Working Principle of Solenoid Valve

What is a solenoid valve?

The solenoid valve is industrial equipment controlled by electromagnetism. It is an automatic basic element to control the fluid. It belongs to the actuator, but not limits to the hydraulic pressure and pneumatic control. In the industrial control system, the solenoid valve is used to regulate the direction, flow rate, speed and other parameters of the medium. The solenoid valve can coordinate with different circuits to realize the anticipated control, with both control precision and flexibility being guaranteed.

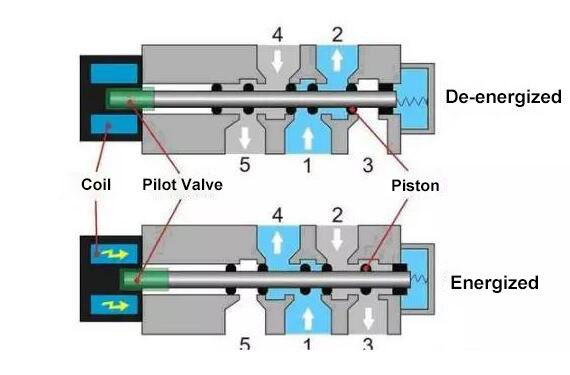

The solenoid valve is constituted by the solenoid coil and magnetic core. It is the valve body containing one or several holes. When the coil is get through or cut off with power, the operation of the magnetic core will result in that the fluid passes through the valve body and is cut off, so as to reach the goal of changing the fluid direction. The electromagnetic component of the solenoid valve is constituted by the fixed iron core, movable iron core, coil and so on. The valve body is constituted by the slide valve core, slide valve harness and spring base. The solenoid coil is installed on the valve body directly while the valve body is enclosed in the seal pipe, so as to constitute a simple and compact combination.

How a solenoid valve works?

The solenoid valve has an enclosed chamber inside and ventilated holes in different positions. Every hole is connected with different oil pipes. The chamber has a piston in the middle. The two sides are two pieces of electromagnets. The electrifying magnetic coil will attract the valve body to its side, so that different oil outlets will be opened or closed through controlling the movement of the valve body. However, the oil inlet is constantly open. The hydraulic oil will enter into different draw-off pipes. The oil pressure will be used to drive the piston of the oil cylinder, which will drive the piston rod and then the mechanical device. In this way, through controlling the current of the solenoid valve, the mechanical movement will be controlled. Furthermore, let's briefly learn about the working principle of two main types of solenoid valve.

1. Direct-acting solenoid valve

- Working principle

When the power is on, the solenoid coil generates the electromagnetic force to lift the closure member from the valve seat to open the valve. When the power is cut off, the electromagnetic force disappears and the spring presses the closure member on the valve seat to close the valve. - Characteristics

It can work normally in the vacuum, negative pressure and zero pressure. However, the diameter normally doesn’t exceed 25mm.

2. Pilot-operated solenoid valve

- Working principle

When the power is on, the electromagnetic force opens the pilot hole and the pressure of the upper chamber decreases rapidly, forming a pressure difference which is low in the upside and high in the bottom around the closure element. The fluid pressure promotes the closure element to move upwards to open the valve. When the power is off, the spring force closes the pilot hole. The pressure through the bypass port rapidly forms a pressure difference which is high in the upside and low in the bottom around the closure element. The fluid pressure drives the closure element to move downwards and close the valve. - Characteristics

The fluid pressure scope has a relatively high upper limit. It can be installed randomly, with the fluid pressure difference condition being satisfied.

Buy 2-way, 3-way and 5-way pneumatic solenoid valve with high performance and low price on ATO.com for your air control.

Kenneth Tachio Joseph,from Nigeria.