What is the Advantage of Globe Valve?

Globe valve is a widely used valve for closing, opening and throttling pipeline media. It is suitable for high-temperature and high-pressure water, steam and oil pipelines in thermal power plants, petrochemicals, and metallurgy. The powerful function of globe valve makes people's industrial production more convenient. Let's take a look at the characteristics of globe valves today.

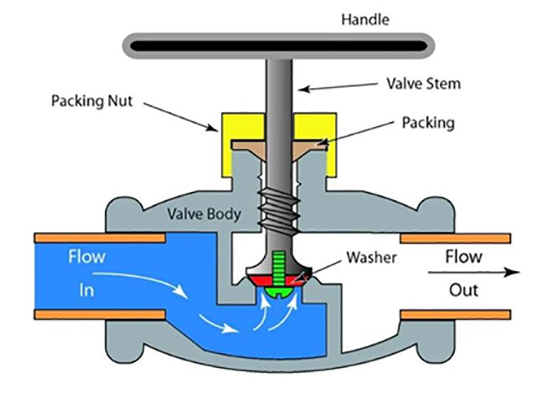

What is the structure of globe valve?

Globe valves are usually composed of parts such as valve body, valve, seat, seal and pin. The valve body is a structure used to fix other components. A valve is a moving part that is used to open or close the valve. When the valve is open, the medium can flow; when the valve is closed, the medium can be prevented from flowing. The seat is also an important part, and it is the part of the valve body designed to install the valve and other parts, while the seal is an important part to make the valve tight, and the pin is the part used to connect the valve and the seat.

Advantages

- Compared with gate valve. The globe valve has a simple structure and is convenient to manufacture and maintain. When the globe valve is opened and closed, there is no relative sliding between the valve disc and the sealing surface of the valve body (except for the tapered sealing surface), so the wear and tear are not serious, the sealing performance is good, and the service life is long.

- When opening and closing, the stroke of the disc is small, so the height of the stop valve is small, but the structural length is large. When closing, because the movement direction of the disc is opposite to the direction of the medium pressure, it must overcome the force of the medium, and the closing torque is large. Therefore, the diameter of the globe valve is limited, and the general nominal diameter is not more than 200mm.

- The flow resistance is large, the medium channel in the valve body is relatively tortuous, the flow resistance is large, and the power consumption is large. Among all kinds of globe valves, the flow resistance of the globe valve is the largest.

- The flow direction of the medium is restricted. When the medium flows through the globe valve, it should be guaranteed to flow from bottom to top in the valve seat channel, so the medium can only flow in one direction.

- The opening height is small (Usually 1/4-1/3 of DN). Usually there is only one pair of sealing surfaces, the manufacturing process is good, and it is easy to maintain. Pneumatic globe valve are widely used, but due to the large opening and closing torque and long structural length, the general nominal diameter is limited to DN≤250mm. The fluid resistance loss of the stop valve is relatively large, thus limiting the wider use of the stop valve.

- In the process of opening and closing, because the friction between the disc and the sealing surface of the valve body is smaller than that of the gate valve, it is wear-resistant. The opening height is generally only 1/4 of the seat channel, so it is much smaller than the gate valve.

- Usually there is only one sealing surface on the valve body and the valve disc, so the manufacturing process is better and it is easy to maintain. Because its filler is generally a mixture of asbestos and graphite, it has a high temperature resistance level. Generally steam valves use globe valves.

- There is no fluid loss, reducing energy loss and improving plant equipment safety. Long service life, less maintenance times and lower operating costs.

- Robust and durable sealing design ensures zero leakage of the valve stem and provides maintenance-free conditions.

- The bellows-sealed stop valve design completely eliminates the shortcomings of ordinary valve stem packing seals such as fast aging and easy leakage. It not only improves the efficiency of energy use, increases the safety of production equipment, but also reduces maintenance costs and frequent maintenance.

Classification

According to the position of the thread on the stem, it can be divided into:

a. Upper threaded stem globe valve: The thread of the globe valve stem is outside the valve body. Its advantage is that the valve stem is not eroded by the medium and is easy to lubricate. This structure is more commonly used.

b. Lower thread stem stop valve: The thread of the stop valve stem is inside the valve body. The stem thread of this structure is in direct contact with the medium, which is susceptible to corrosion and cannot be lubricated. This structure is used in places with small diameter and low temperature.

According to the pipeline direction of the globe valve, it can be divided into:

Straight-through globe valve

DC globe valve

Angle globe valve

Three-way globe valve

The latter two stop valves are usually used to change the flow direction of the medium and distribute the medium.

Precautions

- The globe valve operated by hand wheel and handle can be installed at any position of the pipeline. Hand wheels, handles and micro-motion mechanisms are not allowed to be used for lifting.

- The flow direction of the medium should be consistent with the direction of the arrow shown on the valve body. Globe valves should be used on pipelines or devices with high temperature and high pressure media. Such as thermal power plants, nuclear power plants, high temperature and high pressure pipelines of petrochemical systems.

- Needle valves, instrument valves, sampling valves, pressure gauge valves, etc. can be used for small valves. There is flow adjustment or pressure adjustment, but the adjustment accuracy is not high, and the diameter of the pipeline is relatively small, such as the pipeline with a nominal diameter ≤ 50mm, it should be selected.

- For water supply and heating projects in urban construction, globe valves, balance valves or plunger valves can be used for pipelines with a smaller nominal diameter, such as pipelines with a nominal diameter of less than 150mm. In the process of opening and closing, because the friction of the disc on the sealing surface of the valve body is smaller than that of the gate valve, it is wear-resistant. The opening height is generally only 1/4 of the diameter of the seat channel, so it is much smaller than the gate valve. Usually there is only one sealing surface on the valve body and the valve disc, so the manufacturing process is better and it is easy to maintain.