What is an Industrial Water Chiller?

Industrial water chiller is a kind of water cooling equipment, which can provide constant temperature, constant current and constant pressure. The principle of the chiller is to inject a certain amount of water into the internal water tank of the machine, cool the water through the cooling system of the chiller, and then the water pump inside the machine will inject the low-temperature frozen water into the equipment to be cooled, the frozen water will take away the heat inside the machine, and return the high-temperature hot water to the water tank again for cooling, so as to achieve the function of cooling the equipment by circulating and exchanging cooling.

Industrial Water Chiller Constructure

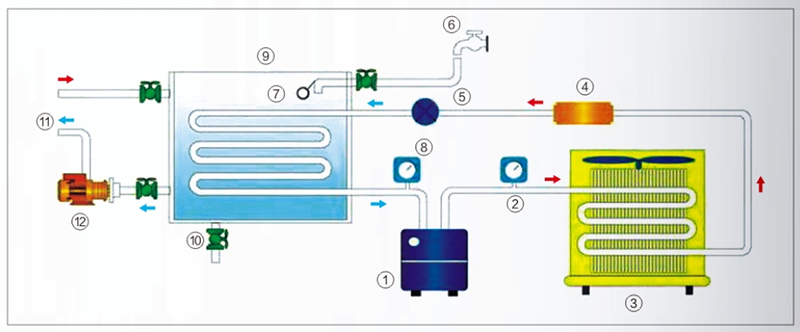

The operation of industrial water chiller works through three interconnected constructure systems: Refrigerant circulation system, water circulation system and electrical automatic control system.

1. Refrigerant circulation system:

The liquid refrigerant in the evaporator absorbs the heat in the water and starts to evaporate. At last, a certain temperature difference is formed between the refrigerant and the water. The liquid refrigerant also completely evaporates into a gaseous state, which is then inhaled and compressed by the compressor (pressure and temperature increase). The gaseous refrigerant releases heat through the condenser and condenses into a liquid. After throttling through the expansion valve (or capillary), it turns into low temperature and low pressure refrigerant and enters the evaporator, completing the refrigerant circulation process.

2. Water circulation system:

The water pump is responsible for pumping the water from the water tank to the equipment to be cooled by the user. After the heat is taken away by the chilled water, the temperature rises and then returns to the chilled water tank.

3. Electrical automatic control system:

Including the power part and the automatic control part. The power supply part supplies power to the compressor, fan, water pump, etc. through the contactor. The automatic control part includes temperature controller, pressure protection, time delay device, relay, overload protection and other functions, which can automatically start and stop and protect the water temperature.

| ① | Compressor | ② | High pressure gauge | ③ | Condenser | ④ | Dry filter |

| ⑤ | Expansion valve | ⑥ | Water supply | ⑦ | Evaporator | ⑧ | Low pressure gauge |

| ⑨ | Water tank | ⑩ | Drain | ⑪ | Refrigerated water | ⑫ | Pump |

Wide Application of Industrial Water Chiller

1. Water chiller used in the cooling of plastic processing mechanical molding mold which can greatly improve the surface finish of plastic products, reduce the surface striation and internal stress of plastic products, and make the products not shrink or deform. It is convenient for demoulding of plastic products and accelerating the finalization of products, thus greatly improving the production efficiency of plastic molding machine.

2. Water chiller is applied to the lubrication of the spindle of CNC machine tools, coordinate boring machines, grinding machines, machining centers, modular machine tools and all kinds of industrial precision machine tools and the cooling of the transmission medium of the hydraulic system, which can accurately control the oil temperature, effectively reduce the thermal deformation of the machine tools and improve the machining accuracy.

ATO.com store provides 3HP, 4HP, ... 20HP air cooled water chillers for selection.