What is a Vacuum Gauge?

A vacuum gauge is a key component for measuring pressure in vacuum equipment, covering a pressure range from ultra-high vacuum to positive pressure (generally less than 2 atmospheres). The measurement accuracy of vacuum gauges of the same type is affected by various factors such as gas composition, temperature, altitude, and installation angle, and needs to be selected and calibrated according to the actual situation. In this blog, ATO Automation will delve into various aspects of vacuum gauges, including their working principles, different types, and applications in various industries.

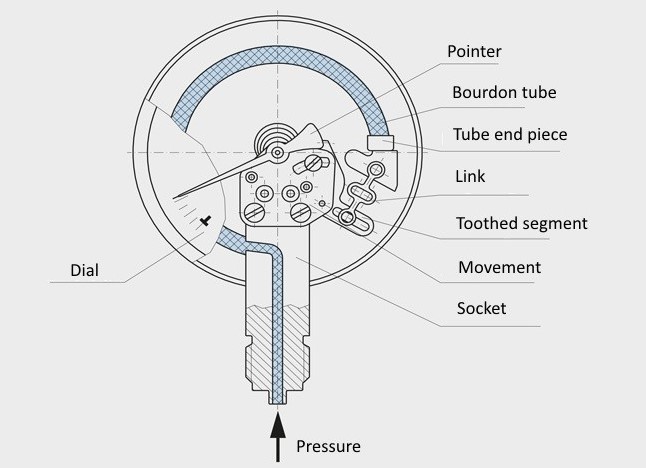

Structure of Vacuum Gauge

A vacuum gauge is an instrument that measures gas pressure, and its working principle is based on the principle of gas molecules colliding with walls in vacuum to generate pressure. The structure of a vacuum gauge mainly includes a vacuum chamber, a pressure sensor, and a reading device.

The vacuum chamber

It is the main part of a vacuum gauge, which is usually made of metal material and has good sealing performance. There is a very low gas pressure in the vacuum chamber, so the collision frequency between molecules is relatively small. When the measured gas enters the vacuum chamber, gas molecules will collide with the wall of the vacuum chamber and produce a physical quantity called gas pressure.

The pressure sensors

It used to measure gas pressure, and their commonly used principles include thermal conductivity, piezoresistive, capacitive, and thermistor methods. Among them, thermal conductivity method is a relatively common principle. It uses the characteristic of the heat generated by the electric heating wire being carried away by the gas for measurement. When the gas pressure increases, the frequency of collisions between gas molecules and hot wires increases, causing the temperature of the wire to rise. The value of gas pressure is obtained by measuring the temperature change of the wire.

The reading device

It is used to display and record the measured gas pressure values. Common reading devices include pointer pressure gauges, digital pressure gauges, and computers. They can convert the electrical signals measured by pressure sensors into corresponding pressure values and present them through a display screen or other means.

In general, the working principle of a vacuum gauge is based on the pressure generated by the collision of gas molecules with a wall in vacuum. The gas pressure is measured by a pressure sensor, and the pressure value is displayed by a reading device. This measurement method is widely used in scientific research, industrial production, and laboratory fields.

Types of Vacuum Gauge

According to the different physical mechanisms used in the measurement principle of vacuum gauges, vacuum gauges can be mainly divided into three categories: utilizing mechanical properties (such as Bourdon vacuum gauges and thin film capacitance gauges), utilizing gas dynamic effects (such as Pirani resistance gauges and thermocouple gauges), and utilizing charged particle effects (hot cathode ionization gauges and cold cathode ionization gauges).

In industry, it is divided into the following levels based on the degree of vacuum:

- Low vacuum 105~102Pa

- Medium vacuum 102~10-1Pa

- High vacuum 10-1~10-5Pa

- Ultra high vacuum<10-5Pa

For each level of vacuum, the optimal measuring instrument is different. Specifically, if it is in the range of medium to low vacuum, Pirani vacuum gauge, capacitive thin film vacuum gauge, and piezoresistive vacuum gauge are usually used for measurement.

Applications of Vacuum Gauge

Aerospace field

The application field of vacuum metrology is very extensive, and aerospace is one of the most important application areas. The static expansion method vacuum foundation standard, ultra-high/extremely high vacuum standard, and other national defense highest vacuum measurement standards developed have been accurately calibrated for a large number of vacuum gauges on various space environmental modeling equipment in China, ensuring the accuracy and reliability of test data. The developed spacecraft cabin door rapid leak detector has been applied to the leak detection of cabin doors and docking sealing surfaces of China's Shenzhou series spacecraft and Tiangong-1 target spacecraft, ensuring the safety of astronauts' lives and the smooth implementation of China's manned spaceflight project. The developed minimal leakage rate leak detection system has been applied to the minimal leakage rate leak detection of the lunar sample sealing and packaging device, providing important metrological support services for the realization of China's scientific goal of lunar sample sampling and return in the third phase of lunar exploration. The developed standard gas injection system has been applied to the precise inflation of rubidium bubbles in China's satellite navigation rubidium atomic clock, contributing to the networking of the Beidou satellite navigation system.

Medical Field

The medical field has always had extremely strict requirements for technical equipment, and vacuum gauges, as a key technical equipment, play an irreplaceable and important role in the medical industry. Medical suction system: Medical suction system is an indispensable equipment in medical places such as operating rooms and emergency vehicles, used to extract secretions and fluids from patients' bodies. The vacuum gauge achieves efficient and safe suction function by creating a negative pressure environment, ensuring the smooth progress of surgery and emergency procedures. Medical gas delivery system: Medical gases such as oxygen, nitrogen, etc. need to be delivered to the patient through pipelines. Vacuum gauges play a crucial role in these delivery systems, ensuring stable gas delivery and meeting the needs of different medical scenarios. Medical injection equipment: In devices such as automatic injectors and injection pumps, vacuum gauges are used to precisely control the injection volume of medication, ensuring accurate delivery of drugs according to predetermined doses and improving treatment effectiveness.

Semiconductor Field

Vacuum gauges and pressure control instruments play an important role in semiconductor manufacturing and vacuum processes. These devices not only provide accurate data to help operators monitor the process, but also help ensure consistency and reliability in the production process. Vacuum gauges are mainly used in semiconductor manufacturing to measure the pressure inside vacuum chambers. They can accurately measure and record vacuum degree through various sensors and measurement technologies, such as ionization gauges, thermocouple gauges, thin film gauges, etc. These data are of great significance for optimizing the process, improving product quality, and preventing equipment failures.

As a one-stop shop for industrial equipment, ATO online store offers various types of high-quality vacuum gauges. If you have any requirements, our competitively priced and reliable products will be your best choice. The application of vacuum technology involves various fields, from aerospace equipment to ordinary light bulbs. The measurement of vacuum degree is undoubtedly the key to vacuum technology, so we need to have a suitable vacuum gauge to assist our work. At ATO, we are committed to providing you with the best vacuum gauges on the market.