What is a Soft Starter?

Three phase asynchronous motor has many advantages, but also has two fatal weaknesses: one is the poor starting performance, the other is poor speed control performance. With the development of power semiconductor technology and application of high power transistors in industrial control field, two typical products greatly improve the two weaknesses of asynchronous motors: Variable Frequency Drive and Soft Starter. The VFD improves the speed control performance of asynchronous motors, while the soft starter improves the starting performance of asynchronous motors.

With various functions such as soft start, soft stop, pump control and timed low speed operation, the 3 phase motor soft starter has incomparable advantages over traditional reduced voltage starter in power equipment control in the industrial and civil construction fields.

Characteristics of Soft Starter

- Soft start: The motor’s terminal voltage increases gradually from the initial setting value to the full voltage within its starting time ts, the motor accelerates smoothly and stepless. The motor can also be adjusted within ts (generally between 0.5~ 60s), which is conducive to the coordination with low-voltage circuit breakers, and preventing tripping of instantaneous release of the low-voltage circuit breaker by mistake at the starting.

- Pump control function: When the pump starts and stops, the flow dashes the pipeline and causes serious water hammer effect. Some measures have been taken to eliminate the water hammer effect in watercourse specialty, but if a soft starter with pump control function is adopted, the water hammer effect can be completely eliminated, thus reducing the workload of mechanical maintenance, saving system maintenance costs and guaranteeing reliable water supply.

- Overload protection function: Overlaod protection of general motors is realized by thermal elements, but thermal elements may not easily avoid the malfunctions caused by the starting current of motor at its starting process. To avoid malfunctions, users often increase the operation current of thermal elements, as a result, the overload protection may not have sufficient sensitivity, and it can’t fully play its functions. The built-in overload protection function of soft starter selects different release characteristic curves according to the light load and heavy load (namely the length of starting time), so as to avoid incorrectly tripping in starting process.

- Parameter testing function: The soft starter can choose to display the motor’s operation parameters in the display panel through keys, such as three-phase voltage value, three-phase current value, power factor and running time, without adding any other instrument. This function makes it easy for users to query various parameters of motor in operation.

- Regular automatic test of fire pump: The fire pump belongs to fire emergency facility and is usually in spare state for long terms, so it gets stuck easily. If it can’t operate normally in case of fire, it will affect the fire fighting rescue and result in serious consequences. The soft starter has functions of timing and low speed operation, it can start and stop automatically and regularly according to the time set by the user, thus conducting automatic testing and detection to the fire pump, improving the reliability and emergency responsibility of fire fighting facilities.

Principle and Wiring Connection of Soft Starter

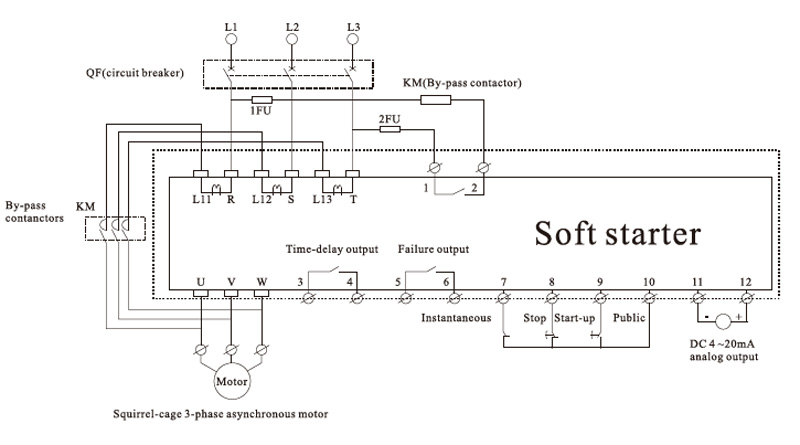

Soft starter uses three-phase reverse parallel thyristor as voltage regulator and connects it between power supply and motor stator (The detailed wiring schematic diagram is shown in the figure). When starting the motor with soft starter, output voltage of the thyristor increases gradually and the motor accelerates gradually until the thyristor is fully turned on. The motor works on the mechanical characteristics of rated voltage to realize smooth start and reduce start current, thus avoiding start-up over-current tripping. When the motor reaches the rated speed, the start-up process ends.