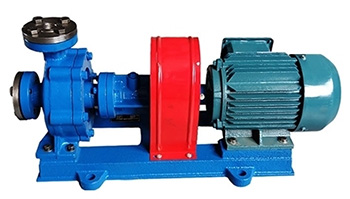

What is a Hot Oil Pump?

A hot oil pump is a mechanical device specially designed for conveying and circulating high-temperature oil or hot oil. It plays a vital role in many industrial fields, especially in systems that require heat conduction, heating or temperature control through high-temperature media. Hot oil pumps are widely used in many industries such as chemical industry, petroleum refining, metallurgy, heat treatment, food processing, etc., for oil and liquid transportation in high-temperature working environments.

Working principle of hot oil pumps

The working principle of hot oil pumps is similar to that of common pump equipment. They all transport liquid from low-pressure areas to high-pressure areas through the rotation of impellers or other moving parts. Specifically, the basic working process of hot oil pumps is: when the motor or other driving device drives the impeller in the pump body to rotate, the liquid is sucked into the pump body, and the high-speed rotation of the impeller generates centrifugal force, causing the liquid to flow to the outlet of the pump to complete the delivery of hot oil.

The pump body, bearings, seals, impellers and other components of the hot oil pump are usually made of special materials that are resistant to high temperature, corrosion and oxidation to ensure its safety and reliability under high temperature and long-term operation.

Main features of hot oil pumps

The main feature of hot oil transfer pumps is that they can work stably and for a long time in high temperature environments. Since the oil that needs to be transported is often at a high temperature (usually between 150°C and 350°C, and even higher in some cases), the key components of hot oil pumps must be made of high temperature resistant materials, such as alloy steel, stainless steel or high-performance plastics, to prevent aging, deformation or cracking in high temperature environments.

The sealing problem of high temperature oil is very important. Hot oil pumps must be equipped with reliable sealing devices to prevent leakage of high temperature oil and ensure the safe operation and environmental protection of the system. Common sealing methods include mechanical seals, packing seals, etc.

The hot oil pump needs to have high working efficiency and stability, because in many industrial processes, the hot oil pump may need to run continuously for hours or even days. Efficient pumps can effectively reduce energy consumption and operating costs, while improving the overall performance of the system. Some hot oil pumps are equipped with adjustable flow and pressure control devices, which can accurately control the oil flow rate and delivery pressure according to actual needs.

Application fields of hot oil pumps

Hot oil pumps are widely used in the following major fields:

Petroleum and chemical industry: In the process of petroleum refining and chemical production, hot oil pumps are used to transport and circulate hot oil to ensure the temperature control of equipment such as reactors and exchangers. Hot oil pumps can efficiently and stably transport high-temperature oil to ensure the smooth progress of the production process.

Metallurgy and heat treatment: In the metallurgical industry, especially in the process of metal heat treatment, hot oil pumps are often used to heat metal workpieces to ensure the uniformity and stability of their temperature in the heating furnace. This is crucial to improving the quality of metal materials.

Food processing and pharmaceutical industry: In some food processing and pharmaceutical processes, hot oil pumps are used to provide the required high-temperature heat source and maintain temperature stability. For example, in frying, baking, sterilization and other processes, hot oil pumps are indispensable equipment.

Boiler heating system: Hot oil pumps are also widely used in boiler systems as part of heat exchange and heating devices to ensure that the hot oil in the boiler system can circulate efficiently, thereby providing the required heat energy.

Solar thermal utilization system: In the solar thermal power generation system, the hot oil pump, as a heat transfer medium, is responsible for transferring the heat obtained from the solar collector to the steam generator or heat storage tank to help achieve efficient use of energy.

Selection and maintenance of hot oil pumps

When purchasing a hot oil pump, you first need to understand the temperature range, flow requirements and pressure requirements of the working environment. In addition, it is crucial to choose the appropriate sealing form, high temperature resistant material and pump type compatible with the system (such as centrifugal pump, gear pump, screw pump, etc.).

The maintenance of the hot oil pump directly affects its operating life and efficiency. Regularly check the status of the pump body, bearings and seals, and replace worn or aged parts in time to avoid the hot oil pump from affecting the normal operation of the entire production system due to failure. At the same time, the impurities and sediments in the pump should be cleaned regularly to ensure smooth flow of hot oil.

As an important equipment for high-temperature oil transportation, the hot oil pump plays an indispensable role in many industrial fields. High quality hot oil pump for sale on ATO.com. By efficiently and stably transferring heat, it helps various process flows maintain the required temperature conditions and ensures the smooth progress of production. With the continuous advancement of industrial technology, the design and manufacturing technology of hot oil pumps are also constantly improving, and will play an important role in more fields in the future.