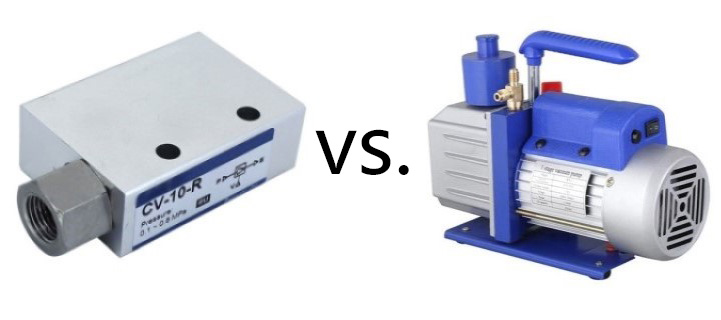

Vacuum Generator vs. Vacuum Pump

In various industrial and scientific applications, the application of vacuum technology is becoming increasingly important. Vacuum generators and vacuum pumps are two common devices that play a crucial role in generating and maintaining vacuum environments. ATO industrial automation provides an in-depth comparison of these two devices, with a focus on their stability.

Operational Principle

Vacuum generators typically generate vacuum by compressing air or gas, using the negative pressure generated by the compressed gas to adsorb or move objects. This type of device is usually designed simply and is suitable for applications that require lower vacuum levels, such as the application of suction cup adsorption robots in automated production lines.

In contrast, a vacuum pump is a device that uses mechanical or physical principles to eliminate gas molecules. Its working principle includes principles such as negative pressure, molecular impact, and centrifugal force, which can more efficiently eliminate gas molecules and form a higher vacuum degree. Vacuum pumps are divided into various types such as mechanical pumps, molecular pumps, diffusion pumps, etc., with different application scenarios and advantages and disadvantages.

Advantages and Disadvantages

Advantages of Vacuum Generators

- Simplicity: Vacuum generators typically feature simple designs and operation, making them easy to install and maintain.

- Cost-Effective: Compared to vacuum pumps, vacuum generators are often more affordable, making them suitable for budget-constrained applications.

- Suitable for Low Vacuum Levels: They perform well in applications requiring lower vacuum levels, such as suction cup adhesion and basic material handling.

- No Additional Equipment Required: In most cases, vacuum generators do not require additional equipment or gas sources, only requiring power to operate.

Disadvantages of Vacuum Generators

- Limited Vacuum Levels: General Vacuum generators are often limited in the vacuum levels they can achieve, struggling to reach high vacuum levels.

- Slow Speed: Vacuum generation with vacuum generators is slower compared to vacuum pumps, unsuitable for applications requiring rapid vacuum attainment.

- Limited Precision Control: They lack precision in controlling vacuum levels, making them unsuitable for applications requiring precise vacuum control.

- Susceptibility to Environmental Factors: The stability of vacuum generators can be affected by factors such as supply pressure and quality, making them susceptible to fluctuations due to environmental influences.

Advantages of Vacuum Pumps

- High Vacuum Levels: Vacuum pumps can achieve higher vacuum levels, suitable for a wide range of applications requiring elevated vacuum conditions.

- Fast Speed: They generally offer faster vacuum generation compared to vacuum generators, enabling rapid attainment of desired vacuum states.

- Precision Control: Vacuum pumps allow for precise control over vacuum levels, catering to applications with strict vacuum level requirements.

- High Stability: Vacuum pumps provide stable vacuum operations across a wider range of vacuum levels, capable of coping with transitions from low to high vacuum levels.

Disadvantages of Vacuum Pumps

- High Cost: Vacuum pumps typically come with higher initial costs and maintenance expenses compared to vacuum generators.

- Complexity: Operating and maintaining vacuum pumps usually require specialized knowledge and skills due to their more complex design and operation.

- Frequent Maintenance: Due to the presence of mechanical components, vacuum pumps require regular maintenance and upkeep, leading to higher maintenance costs.

- Additional Equipment Required: Some vacuum pumps may necessitate additional equipment or gas sources to achieve optimal performance, adding to system complexity and costs.

Application Scope

Vacuum generators are mainly suitable for lower vacuum levels and relatively simple applications, such as material handling in packaging and assembly lines. They usually come into play when fast and simple vacuum operations are needed.

Vacuum pumps can provide a wider range of vacuum levels, from low vacuum to high vacuum. Therefore, they are widely used in fields that require higher vacuum levels, such as materials science research, medical equipment manufacturing, etc.

Maintenance Requirements

Generally speaking, vacuum generators have lower maintenance requirements. Due to the fact that they usually do not have moving parts and operate within a relatively low-pressure range, maintenance work is relatively simple and the cycle is longer.

Vacuum pumps may require more frequent maintenance as they have mechanical components and may be affected by gas corrosion or wear. Regular maintenance and upkeep are crucial for ensuring its performance and lifespan.

Stability

Vacuum generators typically perform well at lower vacuum levels. Its stability may be affected by the supply pressure, supply quality, and internal components of the generator (such as valves, compressors, etc.), depending on the internal structure and performance of the compression system, which can provide reliable vacuum operation within a certain range.

The stability of all vacuum pumps may be influenced by the design type of the pump (such as rotary vane pumps, turbomolecular pumps, etc.), sealing performance, and the degree of wear of mechanical components. However, they are able to provide stable vacuum over a wider range of vacuum levels, with the ability to cope from lower to higher vacuum levels.

Conclusion

Although vacuum generators and vacuum pumps are both devices that generate vacuum environments, their working principles, advantages and disadvantages, and application scenarios are different. If it is necessary to generate low vacuum in the atmospheric environment or to control the vacuum more accurately, a vacuum generator is a good choice. If higher exhaust speed and vacuum degree are required, or used in various different environments, the vacuum pump will better meet the requirements. When choosing, it is necessary to consider the specific needs and budget comprehensively.