Three Phase Induction Motor Starting Methods

The starting methods of three phase induction motor generally are direct-on-line starting, reduced-voltage starting and soft starter.

Direct-on-line starting

This kind of starting mode is the most basic and simplest in the motor starting. The method is characterized by less investment, simple equipment and small quantity. Although the starting time is short, the torque is smaller at starting and the current is large, which is suitable for starting small capacity motors.

Reduced-voltage starting

The reduced-voltage starting method can be introduced into medium and large size induction motors to restraint the starting current. When the motor finishes the starting, it will resume to full pressure working. However, the result of reduced-voltage starting will lower down the starting torque. Therefore, the reduced-voltage starting is only suitable for starting the motor under no-load or lightly loaded condition. Some common reduced-voltage starting methods are as follows.

- Stator circuit series resistance starting

A three-phase electric reactor is inserted into the circuit of motor stator windings. The electric reactor can be simply considered as coil, which can produce induced electromotive force to reduce the direct input power frequency voltage. - Star-delta starting

In the normal operation, 3 phase induction motor whose stator winding is stipulated to link in delta connection can be started in star while starting, to reduce the voltage of each phase of motor and then reduce the starting current. After finishing the starting, then it is connected in delta.

Star-delta starting is widely used because of its advantages including simple starting equipment, low cost, more reliable operation and easy maintenance. - Autotransformer starting

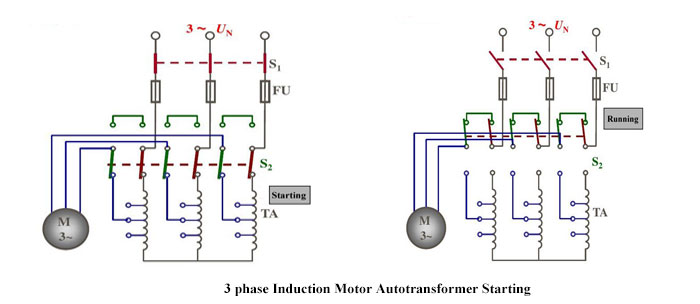

Autotransformer reduced-voltage starting refers that the reduced voltage of grid power is attached to the motor stator windings until the speed approaches to a steady value and then the motor is connected to the power grid.

At starting, the switch is pulled to the “start” position, and the autotransformer is linked to the grid followed by connection to the stator windings of motor to achieve reduced-voltage starting. When the rotation speed approaches to the rated value, the switch will be pulled to “running” position, and the motor directly access to the grid under full pressure operation through cutting off autotransformer.

Autotransformer reduced-voltage starting is introduced into the star connection for the large capacity motor or normal operation with certain load starting. According to the load, transformer tapping is chosen according to receive required starting voltage and starting torque. At this moment, the starting torque is still weakened, but not reduced by one-third (compared with the star-triangle reduced-voltage starting). However, the autotransformer is large-sized and light weight with high price and inconvenience maintenance, which is not allowed to move frequently.

Soft starter

Soft starter is a new type control device whose main advantages include soft starting, light load and energy saving, and quickness. One of the most important features is that the electronic circuit is conducted in the silicon controlled rectifier of motor under the tandem connection of power supply. Using the soft starter to connect the power supply with the motor and different methods to control the conduction angle in silicon controlled rectifier can make the input voltage of motor increase gradually from zero and transfer all the voltage to motor from the beginning to the end, which is called soft starting. When starting in this way, the torque of motor will gradually increase with enhancive speed. In fact, the soft starter is a voltage regulator that only changes the voltage without altering the frequency at starting.