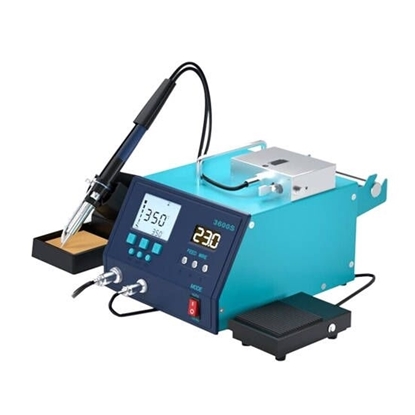

Soldering Station

50W Digital Soldering Station, 110V/220V

65W Soldering Station, 110V/220V

70W Digital Soldering Iron Station, 110V/220V

90W Digital Soldering Station, 110V/220V

120W Digital Soldering Station, 110V/220V

150W Digital Soldering Station, 110V/220V

A soldering station is a tool used for soldering electronic components onto a circuit board or other electronic devices. It consists of a power supply, a soldering iron, and a temperature control unit.

The soldering iron is the main tool used for melting and joining the solder. The temperature control unit ensures that the temperature of the soldering iron remains constant throughout the soldering process, preventing damage to the components being soldered.

Soldering stations come in different sizes and configurations, with different power ratings and temperature control options. They can be used for a variety of electronic projects, including repairing electronics, building circuits, and soldering wires.

Soldering station prices as listed on the website. Digital soldering station for beginners and hobbyists, anyone can use it very well, the temperature of the iron is easy to adjust, the heating speed is fast, the handle is comfortable, large digital display allows temperature to be seen everywhere. The ATO soldering station will let you enjoy working on the circuit board.

How to choose the right soldering station for my needs?

Choosing the right soldering station depends on your specific needs and preferences. Here are some factors to consider when selecting a soldering station:

- Temperature Control: Look for a soldering station with adjustable temperature control. Different types of solder require different temperatures, so being able to adjust the temperature is important.

- Power and Wattage: The power and wattage of the soldering station will determine how quickly it heats up and how effectively it melts solder. Higher wattage soldering stations are usually more efficient and powerful, but they can also be more expensive.

- Types of Tips: Different soldering stations come with different types of tips. Consider the type of work you will be doing and choose a soldering station with tips that will be suitable for your needs.

- Durability and Build Quality: Look for a soldering station that is well-built and durable, with a sturdy base and a comfortable handle.

- Brand and Warranty: Consider the reputation of the brand and the warranty offered with the soldering station. A good warranty can give you peace of mind and protect your investment.

- Accessories: Look for a soldering station that comes with accessories such as a stand, cleaning sponge, and extra tips.

- Price: Finally, consider your budget. Soldering stations can range from relatively inexpensive to quite expensive, so choose one that fits your budget and meets your needs.

By considering these factors, you can choose a soldering station that will be well-suited for your specific needs and preferences.

What temperature should I set my soldering station to?

The temperature you should set your soldering station to will depend on the type of solder you are using and the size of the components you are working with. As a general rule of thumb, most lead-based solders melt at around 370-400°C (700-750°F) and lead-free solders melt at around 420-450°C (800-840°F).

If you are working with small or delicate components, you may want to use a lower temperature to avoid damaging the parts. On the other hand, if you are working with larger components or heavier gauge wire, you may need a higher temperature to get the solder to flow properly.

It's important to note that different soldering stations may have different temperature ranges and accuracy, so it's a good idea to refer to the manufacturer's instructions and experiment a bit to find the optimal temperature for your specific setup and project.

What is the soldering station used for?

A soldering station is a tool used to join two pieces of metal or electronics components together using a process called soldering. The station consists of a power supply, a temperature-controlled soldering iron, and a stand to hold the iron when not in use.

The soldering iron is heated up to the melting point of the solder, which is usually a metal alloy, and then used to heat up the parts to be joined. The solder is then melted and applied to the joint, where it cools and solidifies, creating a strong and reliable electrical connection.

Soldering stations are commonly used in electronics repair, circuit board assembly, and other applications that require precise and controlled heat for soldering small components. The temperature control feature of the soldering station ensures that the soldering iron maintains a constant and accurate temperature, which is critical for producing high-quality solder joints.

What types of soldering stations are available, and how do they differ?

There are several types of soldering stations available in the market, each with its own advantages and disadvantages. Some of the most common types of soldering stations are:

- Analog Soldering Station: These are basic soldering stations that come with a temperature dial to adjust the temperature of the soldering iron. They are relatively cheaper compared to other types of soldering stations and are suitable for basic soldering tasks.

- Digital Soldering Station: These are more advanced soldering stations that come with a digital display to show the temperature of the soldering iron. They offer more precise temperature control and are suitable for complex soldering tasks.

- Temperature-controlled Soldering Station: These are soldering stations that come with a built-in temperature sensor that automatically adjusts the temperature of the soldering iron according to the requirements of the task. They are ideal for soldering delicate components that require a precise temperature.

- Hot Air Soldering Station: These are soldering stations that use hot air to melt the solder and bond the components. They are suitable for soldering surface-mount components and are often used in electronics manufacturing.

- Desoldering Station: These are soldering stations that come with a built-in desoldering tool to remove components and clean up solder joints. They are ideal for repairing and salvaging electronic components.

- Rework Station: These are soldering stations that combine the features of a soldering station and a hot air gun. They are ideal for repairing and reworking electronic components and PCBs.

Overall, the type of soldering station you choose will depend on your specific requirements, budget, and the complexity of the soldering tasks you need to perform.

How to maintain a soldering station?

Maintaining a soldering station is important for ensuring that it works properly and lasts for a long time. Here are some tips on how to maintain a soldering station:

Keep it clean: Regularly clean the soldering station with a soft cloth to remove any dust or debris that may have accumulated. This will prevent dirt and debris from getting into the soldering iron or affecting the quality of your soldering.

- Use the right tip: Make sure to use the appropriate tip for the job. Different types of tips are available for different applications, such as fine or wide tips. Using the right tip will ensure optimal performance and prolong the life of the tip.

- Replace the tip when necessary: Over time, the tip of the soldering iron may become worn or damaged. When this happens, replace the tip to maintain optimal performance.

- Keep the iron tinned: To prevent oxidation, it's important to keep the soldering iron tinned. This means applying a thin layer of solder to the tip of the iron when it's not in use. This will prevent the tip from corroding and prolong its life.

- Keep the sponge moist: Most soldering stations come with a sponge to clean the tip of the iron. Make sure to keep the sponge moist by adding a small amount of water to it regularly. This will prevent the sponge from drying out and becoming ineffective.

- Store it properly: When you're not using your soldering station, make sure to store it in a dry and safe place. This will prevent it from getting damaged and ensure that it's ready to use the next time you need it.

By following these simple tips, you can keep your soldering station in good condition and ensure that it performs well for years to come.

Can I use any soldering iron tip with my soldering station?

Not all soldering iron tips are compatible with all soldering stations. It's essential to check the specifications of your soldering station to ensure that you're using the appropriate tips.

Most soldering stations have a specific type of tip that is compatible with them, and they may even have their brand of soldering iron tips that are recommended for use with their station. Using an incompatible tip may result in poor performance, inconsistent heating, or damage to the soldering station.

When looking for replacement tips, be sure to check the tip's size and shape, as well as the heating element's wattage and voltage, to ensure that it will work with your station. Additionally, consider the intended use of the tip, as some tips are better suited for specific soldering tasks, such as fine or large-scale soldering.

In summary, you should use the soldering iron tips that are recommended by the manufacturer of your soldering station or those that are specifically designed to be compatible with your station.