Magnetic Stirrer for Pharmaceutical Equipment

Stirrers, as one of the most commonly used moving equipment, are widely used in chemical, food, dye, cosmetic, and pharmaceutical industries. At present, magnetic stirrers are becoming a popular trend in the biopharmaceutical industry.

Stirrers, as one of the most commonly used moving equipment, are widely used in chemical, food, dye, cosmetic, and pharmaceutical industries. At present, magnetic stirrers are becoming a popular trend in the biopharmaceutical industry.

The stirrer is a device that forces liquid and gaseous media to convection and mix them uniformly. Mixers of all kinds have been in use long before the Industrial Revolution. After the industrial revolution, the application of agitators has become more and more diversified and specialized. The current application of agitators and their knowledge are based on the continuous accumulation and improvement of previous production and life practices.

Stirrer type, size, and rotational speed all affect the distribution of stirring power between bulk flow and turbulent pulsation. In general, the power distribution of a turbine agitator is favorable for turbulent pulsation, while a propeller agitator is favorable for bulk flow. For the same type of agitator, under the condition of the same power consumption, the power of the agitator with large diameter and low rotation speed is mainly consumed in the overall flow, which is conducive to macroscopic mixing. Small-diameter, high-speed agitator, the power is mainly consumed by turbulent pulsation, which is conducive to micro-mixing.

As biopharmaceuticals place higher requirements on sterility and risk control of stirrer shaft seals, magnetic stirrers have become the mainstream of the market and continue to move towards simplicity, high torque, high shear or very low shear, bearing the direction of material safety, easy on-line cleaning and on-line sterilization. For example, a magnetic stirrer for bioreactors, a magnetic stirrer for high shear homogenization, etc. Whether it can be proved that the mixer can be cleaned and sterilized online, and the safety of bearing materials has become the gold standard before the selection of biopharmaceutical mixers.

The working principle of the desktop magnetic stirrer is to use the property of the same sex repulsion of magnetic substances to push the magnetic stirring bar to rotate by constantly changing the polarities of the two ends of the base; the disadvantage is that the energy conversion efficiency is low, and it is only suitable for small volume liquid stirring.

The working principle of the industrial magnetic stirrer is that the inner and outer magnetic steels are separated by an isolation sleeve. After being driven by the motor, the inner and outer magnetic steels generate magnetic coupling to achieve the purpose of transmission. Mostly used in pumps, magnetic pumps can achieve complete leak-free and the most efficient energy conversion. Corresponding to the lower magnetic stirrer is the upper magnetic stirrer. Since the risk brought by the shaft seal is still not completely removed, the application field is very limited.

Since stirring is an experimental science, the scale-up of agitators is a complex problem related to the technological process. So far, it can only be scaled up through experience, and extrapolated to an industrial scale based on the obtained scale-up basis. At present, the magnetic stirrer mainly relies on the simulation test of the common buffer as the main mode solution of the manufacturer, and the finalization and amplification are made on this basis. All customized models are improvements on the basis of standard models, such as material customization, power customization, paddle shape customization, etc. Correct selection and selection of suitable mixers have become a problem that must be solved in front of users.

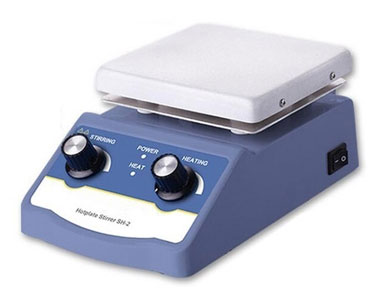

The magnetic stirrers provided by ATO.com are used for liquid mixing, mainly for stirring or simultaneously heating and stirring liquids or solid-liquid mixtures with a certain viscosity. 1L, 3L, 5L laboratory hot plate magnetic stirrer, heating mantle with magnetic stirrer and digital heating mantle with stirrer for your choices, shop online now!