Linear Slide: Applications, Advantages and Working Principle

Linear slide, also known as linear guide or slide rail, is a mechanical component used to achieve linear motion. Its basic principle is based on the reduction of rolling friction to achieve high precision, high rigidity, and high-speed linear motion. This blog will provide a detailed introduction to linear slides.

Working Principle

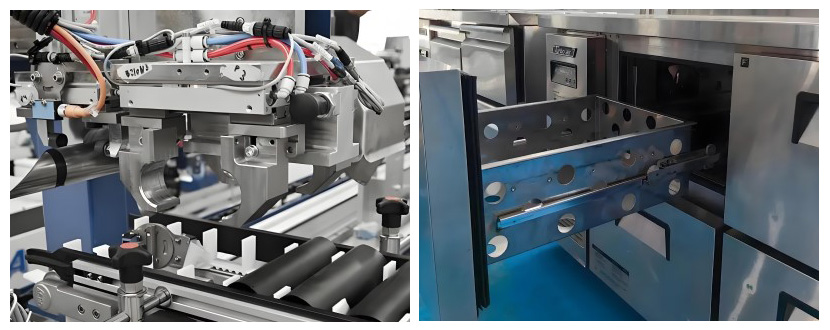

Linear slide mainly consists of slide rails, sliders, and balls or rollers. The slide rail is fixed on the foundation structure, while the slider is connected to the slide rail through balls or rollers. The ball or roller rolls between the slide rail and the slider, reducing frictional resistance and allowing the slider to easily slide on the slide rail.

The accuracy and stability of a linear slide mainly depend on the manufacturing accuracy of the slide and slider, as well as the accuracy of the ball or roller. The surface roughness, parallelism, and straightness of the slide and slider must be controlled within a very high precision range to ensure the straight-line motion accuracy and stability of the slider.

In addition, the rigidity and load-bearing capacity of linear sliding rails are also important performance indicators. The structural design of slides and sliders, as well as the arrangement of balls or rollers, will affect their rigidity and load-bearing capacity. Through reasonable structural design and material selection, linear sliding rails can have sufficient rigidity and load-bearing capacity to meet the needs of various application scenarios.

Application Area

Linear slides play a crucial role in various industrial and engineering applications, with a wide range of applications. ATO provides linear motion system, which not only a linear slide or guide rail, it is a linear motion system. The following are some of the main application areas.

Automation and manufacturing: Linear slides are widely used in automated production lines and manufacturing processes. They can be used for moving and locating workpieces, parts or tools, as well as controlling the movement of robots and automation systems. By integrating with the control system, the linear slide can achieve precise position control and motion trajectory, thereby improving production efficiency, reducing costs, and improving product quality.

Machine tools and processing equipment: Sliding blocks installed on linear guides can be used to support and move cutting tools or workpieces. In CNC machine tools and other machining equipment, linear slides provide stable linear motion and can be used to achieve high-precision cutting, milling, drilling, and grinding operations.

Packaging and logistics: Linear slides play an important role in packaging equipment and logistics systems. They can be used to move products or packaging boxes from one location to another, achieving efficient packaging and logistics processes. Through fast and accurate positioning and transportation, linear slides can improve production efficiency and reduce logistics costs.

3D printing and CNC engraving: Printing heads or tools installed on linear slides can be used to control the movement of 3D printers and CNC engraving machines. The linear slide provides precise linear motion, which can be used to achieve complex part manufacturing and precise carving operations, bringing enormous development potential to the manufacturing and innovation fields.

Laboratories and research: Linear slides are widely used in scientific laboratories and research institutions. They can be used for moving and positioning experimental samples, instrument equipment or optical components, as well as controlling the movement and operation during the experimental process. By providing stable and precise motion control, linear slides play an irreplaceable role in scientific research and experimental fields.

Advantages of Linear Slides

Linear slide rails have many advantages, making them the preferred solution in many industrial and engineering applications.

Accuracy: The linear slide provides highly precise linear motion, capable of achieving micrometer level positioning accuracy, suitable for applications that require high-precision positioning and motion control.

Stability: They can provide smooth and stable linear motion, reduce vibration and noise, and help ensure the stability and reliability of equipment and workpieces.

High load capacity: The linear slide rail design is sturdy and can withstand high loads, including vertical and horizontal loads, suitable for heavy-duty industrial applications.

Wear resistance: They are usually made of wear-resistant materials, such as hard metal or plastic, which can be used for a long time without severe wear, extending their service life, improving efficiency, and reducing energy consumption.

Diversity: They can adapt to various application needs, including different loads, speeds, accelerations, and environmental conditions, and can be customized by selecting appropriate models and specifications.

Easy to install and maintain: Linear rails typically have a simple installation process, are easy to integrate into existing systems, and typically require less maintenance work, reducing equipment downtime and maintenance costs.

Flexibility: They have flexible design and configuration options, can be integrated with other components and systems, meet the needs of different applications, and provide customized solutions.

Overall, linear slide is a multifunctional and efficient mechanical device with broad application prospects and potential, providing important support and impetus for the development of various industrial and technological fields.