How to Wire and Set a Digital Rotary Torque Sensor?

ATO digital torque sensor feature a wide capacity range from 0.1/5/300/1000 Nm to 10000 Nm, with optional RS485 as well as other type’s output signals. Equipped with a 7 pin waterproof circular locking connector and 3m cable, the torque sensor can measure both forward and reverse torque. Now, we’re gonna talk about a digital rotary torque sensor from ATO, Model TQS-DYN-200.

This torque sensor has a measurement range from 0.1Nm~10000Nm. It can be customized to transmit analog or digital signals. The 9-pin circular connector meets all signal output requirements.The locking-type circular connector features a quick-release metal latch for secured connection.

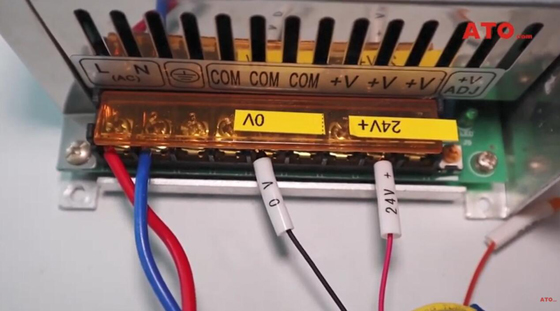

Wiring

The red and black leads are power wires, red for 24V and black for 0V, and connect them to the power supply.

Setting

By default, the LCD screen shows the current torque, power and speed. The key K1 toggles these values to show them individually.

- Long press K1 to display the parameter setting interface.Then short press K1 to switch the parameter lists.

- Long press K2 to switch the items of the selected list.

- Short press K3 to modify the parameters.

- Long press K1 to return to the default interface.

For more details about ATO digital rotary torque sensor wiring and setting, please view the video below. ATO provides different types of torque sensors for you, they are all at economical price. Buy now!