How to Use the Hydraulic Puller?

Hydraulic puller, also known as hydraulic bearing puller, hydraulic gear puller, is an ideal new tool to replace transmission pullers. Easy to operate, labor-saving, and not limited by the site, ATO industrial automation have many models of hydraulic pullers which are compact, flexible, light, small, and easy to carry, suitable for factories and repair sites. There are many types of hydraulic pullers, including integrated hydraulic pullers, separate hydraulic pullers, coupler-specific pullers, mobile hydraulic pullers, separate non-slip hydraulic pullers, and vehicle-mounted hydraulic pullers. Choosing the right puller depends on the task you want to complete and the environment in which you work. For example, if you are using a hydraulic puller for car repairs, you need to choose a hydraulic puller suitable for the car, usually in sizes of 2 to 20 tons. Before working, make sure you have selected the right hydraulic puller for your task.

if you are using a hydraulic puller for car repairs, you need to choose a hydraulic puller suitable for the car, usually in sizes of 2 to 20 tons. Before working, make sure you have selected the right hydraulic puller for your task.

Preparation before Use

After selecting the right hydraulic gear puller for the task, the following checks should be done:

- Check whether the appearance of the hydraulic puller is intact, whether the hydraulic pump, oil tank, hydraulic cylinder, wave pressure oil pipe and other components are fastened and reliable, and ensure that there is no damage or looseness.

- Check whether the hydraulic oil is sufficient and clean. If it is insufficient, it should be replenished in time. If there are impurities, it should be replaced in time.

- Check whether the operating handle and control valve are flexible and reliable to ensure unobstructed operation. Select appropriate puller accessories such as hooks, pull rods, etc. according to actual needs and install them firmly.

Using Steps

- Tighten the oil return valve stem clockwise before use.

- Select a hydraulic puller of appropriate tonnage according to the outer diameter, pulling distance and load force of the object to be pulled to ensure that it is not overloaded.

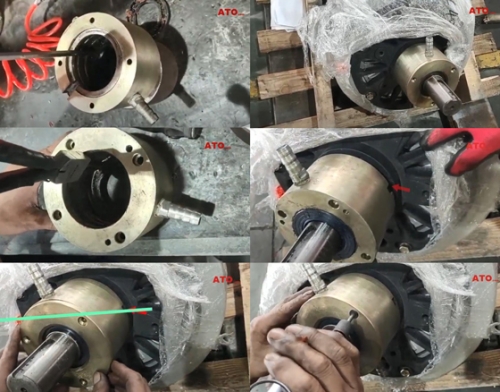

- Place the hydraulic bearing puller on the workpiece to be disassembled, and adjust the position of the hook or pull rod to align it with the center point of the workpiece to be disassembled.

- Move the piston starter rod back and forth to move it forward steadily, and the claw hook will retreat accordingly to pull out the object. Slowly operate the handle to make the hydraulic cylinder generate enough tensile force to start the disassembly process.

- Loosen the oil return valve stem and gently loosen the oil return valve counterclockwise. The piston starting rod gradually retracts under the action of the spring. If the extension distance of the piston starting rod is required to be greater than the effective distance of the hydraulic gear puller piston starting rod during use, it is necessary to stop when the extension reaches the maximum effective distance, loosen the oil return valve rod, and allow the piston starting rod to retract. After adjustment Repeat steps 1-3 again until the pull-out stops.

- When the disassembly is completed, slowly release the tensile force of the hydraulic cylinder to avoid sudden loosening that may cause damage to the workpiece or personal injury.

Using Tips

- During use, avoid excessive stretching or exceeding the rated load capacity of the hydraulic bearing puller to avoid damage to the equipment.

- If empty pumping occurs during use, first loosen the drain screw on the hydraulic hand pump, stand the pump vertically with the head downward and pump it a few times, then tighten the drain screw and continue to use it.

- When there is load, do not remove the quick connector to avoid accidents and damage to the machine parts.

- During the disassembly process, it should be kept stable and avoid excessive shaking or vibration to avoid affecting the disassembly effect or causing damage to the workpiece.

- Pay attention to the working status of the hydraulic oil. If there is any abnormality, stop the machine in time for inspection and troubleshooting.

- When using a hydraulic puller, relevant safety operating procedures should be followed to ensure the safety of the operator.

- It is prohibited to perform maintenance or adjustments during the operation of the hydraulic puller to avoid accidents.

- Operators should wear appropriate protective equipment, such as gloves, goggles, etc. to protect themselves from injury.

Maintenance Recommendations

- Hydraulic gear pullers should be maintained regularly, including replacing hydraulic oil, cleaning oil pipes, oil pumps, control valves and other parts to ensure the normal use of hydraulic pullers.

- During maintenance, first release the pressure in the hydraulic puller, drain the waste oil, and add new hydraulic oil to the hydraulic oil position.

- Check regularly whether the bolts of each part are loose, whether the cylinder has cracks or deformation and repair or replace them in time.

- When storing the hydraulic puller, keep its interior clean and dry, and avoid direct sunlight or long-term humid environment.

- The hydraulic puller body must not be subject to impact or other mechanical damage to prevent normal use from being affected.

- When transporting or storing the hydraulic bearing puller, anti-shock, anti-collision and other measures should be taken to avoid damage to the fuselage.

Troubleshooting

- The hydraulic gear puller is leaking oil. This is usually due to the aging and corrosion of the rubber sealing ring inside the gearbox due to temperature changes. It is recommended to replace the sealing ring. The steps to replace the sealing ring are similar to those written in the previous blog How to Replace Sealing Ring of Magnetic Powder Clutch? Please click on the link for details.

- The hydraulic puller ejector rod does not return to its position. The solution is that after the valve is switched, the automatic retraction of the ejector requires pressure to push it back.

- There is no pressure on the hydraulic puller. Possible causes include insufficient oil level, a leak, or a damaged pressurized check valve. The solution is to check and repair leaks, ensure sufficient oil level, and check the hydraulic control valve. When the hydraulic puller is not in use, the hydraulic puller should be reciprocated without load 2-3 times a month.

- Hydraulic puller rust removal. This can be done by manual rust removal (using abrasive paper), mechanical rust removal (using an electric brush or electric grinding wheel), physical rust removal (sandblasting) or chemical rust removal (using an acidic solution).

- For new or long-standing hydraulic pullers, because there is a lot of air in the cylinder, the piston rod may jump slightly when it is started to be used. You can remove the air vent of the hydraulic equipment of the hydraulic puller (usually in the equipment). While opening the hydraulic system, let the oil cylinder move up and down. When you release the air release valve, air and oil will come out together. After a few minutes, the sound will disappear, and only the oil will come out, and then there will be no more air.

Summarize

Hydraulic pullers are very useful tools, but they need to be selected for the task and environment, and kept clean and maintained before use. Always be safe at work and use hydraulic pullers correctly to generate the required high pressure and force. Before using a hydraulic puller, refer to this manual to ensure that the operating procedures in the manual meet your needs.