How to Operate Motor After Soft Starter Bypass Failure?

In industrial applications, soft starters are essential for ensuring smooth motor startups. However, there may be instances when a bypass output failure occurs, preventing the motor from functioning properly. This article will guide you on how to rely on an external bypass contactor to continue operating the motor in the event of such a failure, ensuring uninterrupted functionality.

When faced with a bypass output failure in industrial soft starter, promptly switching to an external bypass contactor is a reliable backup solution. This ensures that the motor can still start and operate effectively. Here’s how you can do with it.

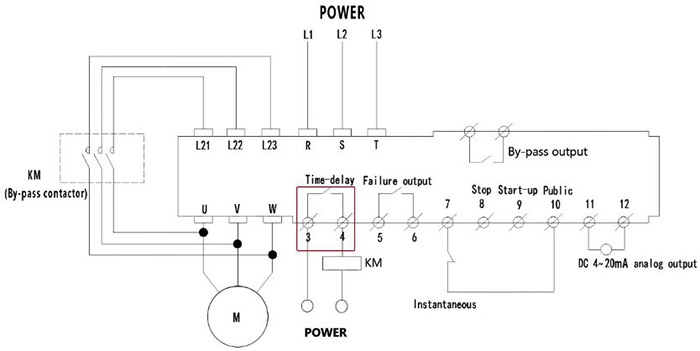

Circuit Diagram

First, make sure that the soft starter and the external bypass contactor are correctly wired to the motor according to the manufacturer’s instructions. Here are some important considerations:

- The terminals 1 and 2 for the bypass contactor connection and terminals 3 and 4 for the time delay function are passive contacts that require an external power source.

- Typically, terminal 7 of the starter must be shorted to terminal 10 or connected to an emergency stop button.

- If terminals 7 and 10 are open, the soft starter will stop working and enter a fault protection state.

Soft Starter Parameter Settings

- Power On: Turn on the soft starter and press the SET key to navigate to parameter group FC.

- Set Parameters: Change FC to 2 to allow parameter modification.

- Access Parameter Group FE: Set the programmable bypass operation output. Select the bypass operation state (FE=9) to ensure that terminals 3 and 4 close when the soft starter operates in bypass mode.

Note: The soft starter offers 5 programmable output modes. When FE is set to 5-9 (or 15-19), terminals 3 and 4 will trigger different working states of the soft starter through programmable relay output. Choose the appropriate output mode based on your specific application needs.

System Testing

Next, proceed with system testing:

- Start the Motor: Press the RUN key on the soft starter control panel to start the motor. When the soft starter switches to bypass mode, the bypass contactor will close.

- Stop the Motor: Press the STOP button on the panel; the motor will gradually slow down and stop operating.

Conclusion

By following these steps and configurations, you can effectively utilize an external bypass contactor as a backup solution to maintain motor operation even in the case of a bypass output failure. This approach not only enhances the reliability of your equipment but also ensures the continuity of your production processes. If you have any questions, you can refer to the video below.