How to Install the Shaft Coupling?

Shaft couplings are mechanical parts used to connect two shafts (driving shaft and driven shaft) in different mechanisms to rotate together to transmit torque. In high-speed and heavy-duty power transmission, some couplings also have the functions of buffering, damping and improving the dynamic performance of the shafting. The coupling consists of two halves, which are respectively connected with the driving shaft and the driven shaft. Most of the general power machines are connected with the working machine by means of couplings.

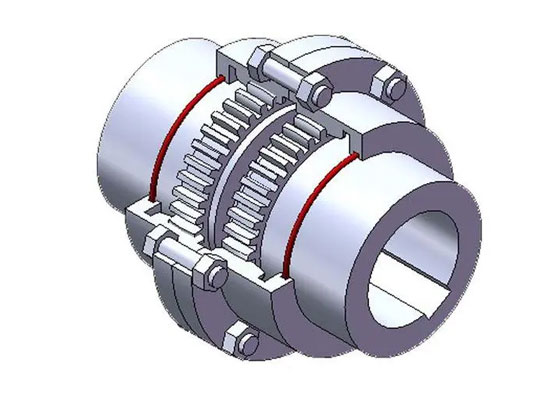

Shaft couplings belong to the category of general mechanical parts and are the most commonly used connecting components for shaft transmission of mechanical products. Commonly used couplings include diaphragm coupling, gear coupling, plum blossom coupling, slider coupling, drum gear coupling, universal coupling, safety coupling, elastic coupling and serpentine spring coupling.

Shaft coupling installation steps

Install the half-coupling on the shaft

- According to the size of the coupling, measure the actual (component) elements of the shaft and the hole, and draw the loading terminal position line according to the regulations.

- Hammering method, used for small size and clearance fit. First apply lubricating oil on the mating, install the key in the keyway, align the half-coupling and install it on the shaft, while pushing and hitting with a hammer (should be hit on the middle backing plate) until it is installed in the terminal position.

- Press assembly, used for interference fit. When the interference is large, use the temperature difference method to fit the press assembly. The temperature difference method assembly is to heat and expand the hole (half-piece coupling), and then install it on the shaft. You can use lubricating oil to heat in the heating box, or use steam heating, electric heating, etc., or use the cooling shaft to make the diameter smaller, and then install the coupling. Coolants for cold loading include liquid nitrogen (cooling temperature up to -190 to 195°C), liquid ammonia (cooling temperature up to -120°C), dry ice plus alcohol and acetone (cooling temperature up to -75°C).

Shaft coupling alignment connection

After the shaft coupling is installed on the journal, the two halves of the coupling are initially aligned by adjusting the shims, so that the centers of the two shafts are roughly aligned, and the end faces of the two halves of the coupling are initially parallel, and then the bolts are put on to prepare to be coaxial. degree adjustment.

Precautions:

- When the half coupling is assembled with the shaft, it must comply with the provisions of the equipment technical documents or construction acceptance specifications, and maintain a certain end face clearance, but the end face of the rigid flange coupling is not allowed to exist.

- When assembling, according to the size of the coupling, mark the insertion depth on the journal to avoid excessive loading.

- When starting to install, keep the end face of the coupling perpendicular to the axis of the shaft, and then start hammering or pressing in to prevent eccentricity.

- When heating with oil, the oil and fire should be absolutely isolated to prevent fire, and the heating place should be free of flammable materials.

Safety precautions for Using shaft couplings

- The coupling is not allowed to exceed the specified axis line skew and radial displacement, so as not to affect its transmission performance.

- The bolts of the coupling shall not be loose or damaged; the keys of the coupling shall be closely matched and shall not be loose.

- The gear coupling and the Oldham coupling should be lubricated regularly, and grease should be added once every 2 to 3 months, so as to avoid severe wear of the gear teeth and cause serious consequences.

- The contact length of the tooth width of the gear coupling shall not be less than 70%, and its axial movement shall not be greater than 5mm.

- The coupling is not allowed to have cracks, if there are cracks, it needs to be replaced (it can be hit with a small hammer, and judged according to the sound).

- The tooth thickness of the gear coupling is worn. When the wear amount of the lifting mechanism exceeds 15% of the original tooth thickness, the running mechanism should be scrapped when it exceeds 25%, and it should be scrapped when there are broken teeth.

- If the elastic ring of the pin coupling and the sealing ring of the gear coupling are damaged and aged, they should be replaced in time.

Daily inspection of the coupling

- Check the coupling body for cracks.

- Check whether the coupling connection is tight and firm.

- Check whether the key connection of the coupling is loose and roll the key.

- Check whether there is radial circular runout and end face runout when the coupling rotates.

- Check whether the coupling lubrication is in good condition.

- Check the integrity of the coupling gear, the wear condition and the meshing condition of the internal and external gears.

Maintenance of the shaft coupling

- Partial disassembly and inspection of equipment, cleaning of specified parts, and dredging of pipes and valves.

- Replace or clean the packing, observe whether the sealing part leaks, adjust the matching clearance of each part of the equipment, and fasten each part of the equipment.

- Refuel and rust-proof the bolts of the motor and water pump.

- Check whether the pressure gauges and control cabinets are normal, and repair or replace them if they are damaged.

- Check the operation of the control cabinet and whether the internal components are normal.

Couplings are sometimes used as a safety device to prevent the connected parts from being subjected to excessive loads and play the role of overload protection. ATO offers a variety of sizes of diaphragm couplings and rigid couplings.