How to Install Pressure Relief Valve in Water Heater?

Sat, Apr 29 by ATO.com

The pressure relief valve is an important part of the water heater, which is a safety device that must be installed on the electric water heater. When the pressure is too high, it will discharge the pressure inside, release the pressure of the inner tank, and prevent accidents caused by the excessive pressure of the water heater. So do you know how to install the pressure relief valve of the electric water heater? Let's take a look now.

Pressure relief valve installation in the water heater

- Before the pressure relief valve is installed, it must be readjusted at the installation site to ensure that the pressure value of the pressure relief valve meets the requirements. Usually, there is an arrow above the pressure relief valve to represent the direction of adding water. According to the direction of this arrow, connect one end of the pressure relief valve to the water tank of the water heater, and the lower end to the cold and hot water valve.

- Within the working pressure range of the spring indicated on the nameplate, the pressure can be adjusted by changing the compression amount of the spring by rotating the adjusting screw. Use a wrench to remove the upper screw, and tighten the pressure relief valve in the direction of the arrow without loosening. Before rotating the adjusting screw, the pressure at the inlet of the valve should be reduced to less than 90% of the opening pressure, so as to prevent the disc from being driven to rotate when the adjusting screw is rotated, so as to damage the sealing surface.

- After the pressure relief valve is installed, check carefully to see if there is any blockage inside it. Because the internal blockage will cause it to be unable to discharge the pressure, which will affect the use of the electric water heater. In order to ensure the accuracy of the cracking pressure, when the working temperature rises, the cracking pressure generally decreases, so it is adjusted at room temperature. When used at high temperatures, the set pressure value at room temperature should be slightly higher than the required opening pressure value.

- The conventional pressure relief valve is used on the occasion of fixed additional back pressure, and the pressure can be adjusted after inspection (the back pressure is atmospheric pressure at this time). Its setting value should be the required opening pressure value minus the additional back pressure value.

- Before using the pressure relief valve, its switch needs to be turned on, as long as the water pressure inside the water tank is too large, the pressure relief function can be realized. If the inner tank pressure of the water heater exceeds 0.8MPa, the pressure relief valve will automatically release the pressure, and let the water flow out along the valve port to ensure the balance of the internal pressure and make it safer to use.

Pay attention to some factors

- Generally, the pressure of the pressure relief valve has a fixed value before it is sold out of the factory. Therefore, before purchasing the pressure relief valve, you must first understand the pressure you need, and contact the manufacturer in advance.

- Before installing the pressure relief valve to the equipment in use, re-adjust the pressure value of the pressure relief valve to ensure that the pressure value of the newly purchased pressure relief valve is suitable for the current equipment.

- The pressure value of the pressure relief valve has a fixed range, which can be learned from the manual. If it does not meet the requirements of the equipment, the pressure can be changed by adjusting the screw of the pressure relief valve.

- Before adjusting the screw of the 2-inch pressure relief valve to change the pressure, remember to reduce the pressure at the valve inlet first. When operating the adjusting screw, ensure that the sealing surface inside the valve will not be damaged.

- Generally speaking, the accuracy of the opening pressure value of the equipment will be affected by the medium, such as temperature. In addition, if the drain pipe of the pressure relief valve is too long and the location of the drain is too far away, then when installing the pressure relief valve, the diameter of the drain pipe should be doubled to prevent damage to the pressure relief valve.

Pay attention to pressure relief valve installation

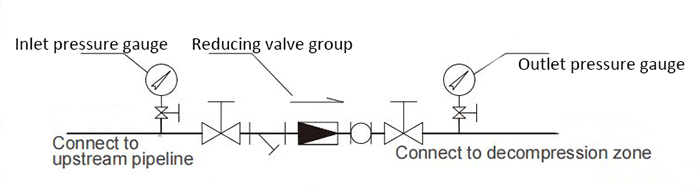

- The pressure-reducing valve can be installed horizontally or vertically, but when installing, pay attention to the direction of the inlet and outlet of the valve body. If the discharge port of the pressure relief valve is far away, the diameter of the discharge pipe should be larger than the specification of the pressure relief valve to stabilize the line pressure in front of the pressure relief valve.

- If there is a control failure during the operation of the pressure relief valve, first check whether the pipeline is blocked, then check whether the water filter of the pipeline is blocked, whether the membrane of the main valve and the pilot valve is broken, whether the main valve and the thick gasket is damaged.

- Before installation, check whether the joints are firm and whether the sealing surface is scratched or damaged. If it is damaged, it should be repaired before installation. If there is pressure in the pipeline (such as a steam pipe), the flange end cover can only be opened for inspection after the valve is removed.

- When the system medium is water, a threaded check valve or a lift check valve can be used as the discharge device. For corrosive media, valves made of corrosion-resistant materials should be used instead of metal valves. For high-pressure medium pipelines, safety check valves should be used instead of ordinary check valves. For high-temperature environments, high-temperature-resistant check valves should be used instead of ordinary slow-closing check valves.

- A through pipe can be set on the pipeline to discharge excess gas and liquid; an exhaust device can also be set on the equipment to discharge excess gas and liquid.

- If the pressure relief valve is not used for a long time, please turn off the main power switch and cut off the air source/water source, and then close all inlet/outlet ports to prevent system leakage.