How to Choose a Laser Module?

Laser modules play an important role in modern technology and are widely used in various fields from industrial processing to scientific research experiments. Choosing the right laser module is essential to ensure system performance and efficiency. ATO industrial automation will introduce in detail the key factors to consider when choosing a laser module to help you make an informed decision.

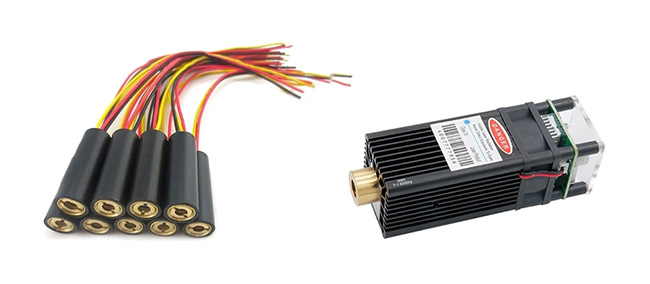

Before choosing a laser module, you need to understand its basic principles to correctly choose a laser module. Laser modules are generally composed of laser diodes, lenses, filters, focus rings, etc. The laser diode is the core component for generating lasers, the lens is used to adjust the shape and focus of the laser beam, and the filter can filter out stray light in the laser beam. The correct use of laser modules requires selecting suitable laser diodes and lenses according to specific needs, and reasonably adjusting the parameters of the laser module. The following will introduce several key factors to consider when choosing a laser module.

Laser type and application requirements

First, understanding the characteristics of different laser types is essential to choosing the right laser module. Semiconductor lasers are small in size and low in cost, suitable for portable devices and simple marking. Solid-state lasers provide high power and stability, suitable for material processing and cutting. Fiber lasers are suitable for high-power applications such as laser cutting and welding with their high efficiency and long life. Choosing the right laser type according to the actual application requirements can ensure the best match between the module performance and the application target.

Power and cooling method

Secondly, the laser power should be selected according to the application requirements. Marking and demonstration usually require lower power, while applications such as material cutting and welding require high power. At the same time, the cooling method has a significant impact on the performance and life of the laser diode module. Air cooling is suitable for low-power laser modules and is suitable for short-term operation. Water cooling is suitable for high-power modules, providing more efficient cooling effects and suitable for long-term operation. Choosing the appropriate power and cooling method can ensure the stability and efficiency of the laser module under the expected working conditions.

Wavelength and beam quality

Third, the wavelength of the laser determines its application range and processing effect. Visible light lasers are suitable for optical demonstrations and simple markings, near-infrared lasers are suitable for high-power applications and material processing, and ultraviolet lasers are used for high-precision micromachining. Beam quality affects the focusing ability and processing accuracy of the laser. The higher the beam quality, the better the focusing effect, which helps to achieve more precise processing.

Size, control method and safety standards

Finally, the size and mounting method of the laser module should meet the system requirements. Compact types are suitable for applications with limited space, while standard types are suitable for conventional equipment. Control methods include analog modulation and digital modulation, which affect the accuracy and flexibility of operation. Make sure that the laser module meets relevant safety standards, such as laser safety level, and is equipped with necessary protective equipment to protect operators and the environment.

Choosing the right laser module requires a comprehensive consideration of factors such as laser type, power, cooling method, wavelength, beam quality, size, control method and safety standards. By evaluating these key factors, you can choose the laser module that best suits your application needs and ensure system performance and efficiency.