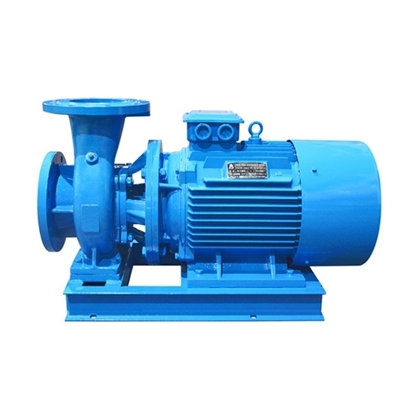

Horizontal Centrifugal Pump

1 hp Horizontal Centrifugal Pump, Single Stage

1.5 hp Horizontal Centrifugal Pump, Single Stage

2 hp Horizontal Centrifugal Pump, Single Stage

3 hp Horizontal Centrifugal Pump, Single Stage

4 hp Horizontal Centrifugal Pump, Single Stage

5 hp Horizontal Centrifugal Pump, Single Stage

7.5 hp Horizontal Centrifugal Pump, Single Stage

10 hp Horizontal Centrifugal Pump, Single Stage

15 hp Horizontal Centrifugal Pump, Single Stage

20 hp Horizontal Centrifugal Pump, Single Stage

25 hp Horizontal Centrifugal Pump, SIngle Stage

30 hp Horizontal Centrifugal Pump, Single Stage

40 hp Horizontal Centrifugal Pump, Single Stage

50 hp Horizontal Centrifugal Pump, Single Stage

60 hp Horizontal Centrifugal Pump, Single Stage

75 hp Horizontal Centrifugal Pump, Single Stage

100 hp Horizontal Centrifugal Pump, Single Stage

The horizontal centrifugal pump is designed according to the principle of centrifugal force. The high-speed rotating impeller blades drive the water to rotate, and the water is thrown out, so as to achieve the purpose of transportation.

ATO offers 3-phase horizontal centrifugal pump of a wide range power rating from 1 hp to 100 hp, inlet/ outlet diameter 25mm (1 inch), 40mm (1~1/ 2 inch), 50mm (2 inch) 65mm (2-1/ 2 inch), 85mm (3 inch) for secletion, installation angle of outlet 0°, 90° and 180°, single stage centrifugal pump has the advantages of simple structure, no vibration during installation and low price.

The centrifugal water pump is not only suitable for urban environmental protection projects, fire protection projects, dyes, construction projects, equipment cooling and other purposes. At the same time, it is also suitable for transporting clean water, sea water and liquids with pH, or liquids with low viscosity and some industrial production liquids.

Horizontal Centrifugal Pump vs. Vertical Centrifugal Pump

Structure

We know from their names and obvious that one is a centrifugal pump with a vertical structure, and the other is a centrifugal pump with a horizontal structure.

Functions

- Vertical centrifugal pump: It is mainly used to transport clean water and other liquids with physical and chemical properties (similar to clean water), used for industrial and urban water supply and drainage, high-rise building pressurized water supply, garden sprinkler irrigation, fire pressurization, long-distance transportation, HVAC Refrigeration cycle, bathroom and other cold and warm water cycle pressurization and equipment. The operating temperature is <80℃.

- Horizontal centrifugal pump: It is used to transport liquids that do not contain solid particles, are corrosive and have a viscosity similar to water. Its operating temperature is -20°C to 120°C.

Connection Type

The vertical pump is a bottom-up superimposed connection form, and the horizontal pump is longitudinally arranged on the left and right and on the base.

Space

Since the vertical centrifugal pump is a vertical structure, the vertical pump does not require much space in terms of floor space. The horizontal centrifugal pump has a much larger footprint than a vertical pump due to its horizontal structure.

Installation form

The two different structures, vertical and horizontal, also make their installations different. For example, the vertical pump is integrally connected, and the installation is very simple. The horizontal pump also needs to be adjusted for accuracy after installation.

Maintenance

The maintenance of the vertical pump is difficult. For example, the upper part of the impeller needs to be removed before it can be carried out. The horizontal pump is relatively easy, as long as the inlet pipe is removed, the impeller can be overhauled.