Electric Butterfly Valve: How it Works?

What is electric butterfly valve?

With the development of electric valves, many well-known valve companies at home and abroad produce electric valves. Electric butterfly valves are important execution units in the field of industrial automation and control. Belonging to a variety of electric valves and electric regulating valves, it is named after the combination of electric actuators and butterfly valves. With the advantages of simple operation and simple structure, the butterfly valve is widely used in textile, power station, petrochemical, heating and refrigeration, pharmaceutical, shipbuilding, metallurgy, light industry, environmental protection and other fields.

Classification

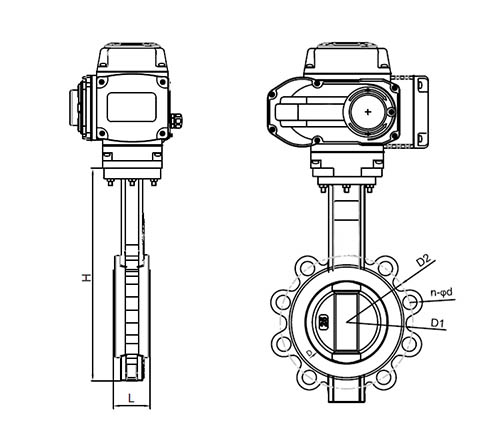

Commonly used electric butterfly valves include flange type  electric butterfly valves and wafer type electric butterfly valves ( For example, ato possess 2” electric wafer butterfly valve). The flange type electric butterfly valve has flanges on the valve and the two flanges on the valve are connected to the pipe flanges with bolts. The wafer type electric butterfly valve uses stud bolts to connect the valve between the two pipe flanges.

electric butterfly valves and wafer type electric butterfly valves ( For example, ato possess 2” electric wafer butterfly valve). The flange type electric butterfly valve has flanges on the valve and the two flanges on the valve are connected to the pipe flanges with bolts. The wafer type electric butterfly valve uses stud bolts to connect the valve between the two pipe flanges.

The product can also be used as shut-off valve, control valve and check valve in piping system. Complete manual control device, electric or pneumatic transmission device, can meet the specific conditions of different working conditions. Meets the strictest quality requirements and enables very durable application. Especially in the metallurgical steel and shipbuilding industry, it has a very high reputation.

With the advancement of technology and the continuous development of the industry, many complex and changeable working conditions appear. And with the changing and complex working environment, the electric butterfly valve, which can automatically control the opening and closing of the pipeline system, is naturally widely used.

So how does the electric butterfly valve complete the complex operation? Let's take a look together.

How to work

The operation process of the electric butterfly valve is mainly to intercept and regulate the flow of medium in the pipeline. When the pipeline medium needs to be adjusted, the pipeline control system sends a corresponding signal, and when the electric actuator receives the signal, the electric device moves the valve stem to drive the butterfly valve, making the butterfly valve plate produce a 90° rotary motion to achieve the opening and closing of the butterfly valve or opening adjustment. Through a series of operations such as the butterfly valve plate, valve seat, and sealing ring, the medium in the pipeline is blocked by the electric butterfly valve, or flow directions are controlled.

The electric actuator of the electric butterfly valve can be divided into on/off type and regulating type. The on/off type electric butterfly valve, for example, on/off type 3" lug butterfly valve can play the role of switch. The adjustable electric butterfly valve is used to adjust the flow rate, and it can accurately adjust the flow rate to a thousand degrees, and it is also a relatively expensive valve.The electric butterfly valve uses electricity to make the electric actuator start to work. The electric actuator drives the valve stem of the butterfly valve to rotate, and the valve plate of the electric butterfly valve is connected to the valve stem, rotating around the valve stem, thereby completely opening and closing the butterfly valve, which achieves the control or regulation of the medium flow in the pipeline.

The electric butterfly valve is like a razor for daily use, and its energy comes from electricity. The operation of the valve is driven by electricity, so as to achieve the function of opening and closing the valve and circulating or shutting off the fluid. For example, the switching value can be adjusted directly by inputting 220V power supply, or a built-in servo module can be input to control the operation by inputting control signal (4 ~ 20mA DC or 1 ~ 5V DC) and single-phase power supply.

The electric butterfly valve essentially controls the switch of the valve through the power signal. The working power supply of the electric butterfly valve is: AC 220V, AC 380V, DC 24V, input signal 4-20mA 0-10V. When the power is turned on, input 220V voltage, the electric actuator starts to work, so input control signal and one-way power supply to control the operation of the system. It can also receive a 4-20mA signal to control the opening of the valve very accurately, and then achieve the control and adjustment of the medium flow, pressure and other parameters.

Because the electric butterfly valve can control the switch of the butterfly valve through the power signal, it can be used as a shut-off valve, control valve and check valve in the pipeline system. The electric butterfly valve is equipped with a manual control device. Once a power failure occurs, it can be temporarily operated manually without affecting the use. The structure of the electric butterfly valve adopts a double eccentric structure design, so that the butterfly valve has a tighter sealing function and reliable sealing performance.

In addition, the sealing material of the valve is made of stainless steel and oil-resistant rubber, which greatly prolongs the service life of the electric butterfly valve; the butterfly valve plate of the electric butterfly valve adopts a frame structure design, which has high strength, large flow area and small fluid resistance. The electrical field also has a two-way sealing function, and the installation is not affected by the flow of the medium or the position of the space, and can be installed in any direction.

Application

Electric butterfly valves are suitable for occasions that require flow regulation. Since the pressure loss of the butterfly valve in the pipeline is relatively large, about three times that of the gate valve, when selecting a butterfly valve, the influence of the pressure loss on the pipeline system should be fully considered, and the firmness of the butterfly valve plate to withstand the pressure of the pipeline medium should also be considered.

In addition, the limitation of the operating temperature of the elastic seat material at high temperature must also be considered. The structural length and overall height of the butterfly valve are small, the opening and closing speed is fast, and it has good fluid control characteristics. The structural principle of the butterfly valve is most suitable for making large-diameter valves. When the butterfly valve is required to be used for flow control, the most important thing is to correctly select the size and type of the butterfly valve so that it can work properly and effectively.