Difference between Spindle Motor and Servo Motor

In terms of usage, the servo motor is mainly responsible for the feed of the machine tool, making the workpiece move to the tool or the tool move to the workpiece, mainly to realize the work of cutting, with higher requirements for torque and control accuracy; while the spindle motor is mainly responsible for driving the spindle of the machine tool, driving the workpiece or the tool head to rotate, with higher requirements for constant power characteristic output to meet the sufficient torque output capability at different speeds. Therefore, when designing, these two motors will make targeted parameter optimization according to their application requirements respectively.

Features of spindle motor

- Sufficient output power: CNC machine tool spindle load nature is similar to "constant power", that is when the machine tool spindle speed is high, the output torque is small; spindle speed is low, the output torque is large, to ensure that the spindle can have sufficient drive power under different working conditions. That is, the requirements of the spindle drive device (spindle motor) to have "constant power" characteristics of the output curve;

- Speed range: to ensure that the CNC machine tools for a variety of different tools, processing materials; adapt to a variety of different machining processes, the requirements of the spindle motor have a certain speed range. But the requirements of the spindle than the feed are lower.

- Speed accuracy: the general requirement of static difference is less than 5%, higher requirements for less than 1%;

- Fast: spindle drive is sometimes used in the positioning function, which requires that it also has a certain degree of rapidity.

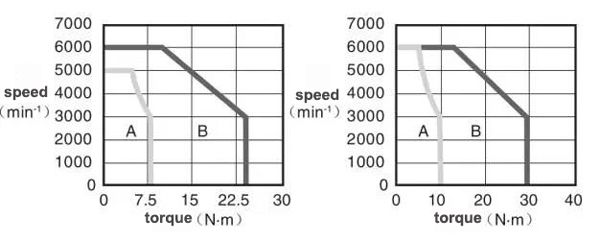

Constant power output curve of the spindle motor

Features of servo motor

- The mechanical characteristics of the servo motor requirements: the servo motor is required to have a small speed drop, in a certain speed range can maintain a constant torque output, and static stiffness.

- The need to achieve high-speed control response: mainly in the contour processing, especially the curvature of the processing object for high-speed processing, the servo motor speed, and torque control response time has very strict requirements.

- The motor itself has a wide range of speed regulations: used to meet the CNC machine tools adapted to a variety of different tools, processing workpiece materials, and can adapt to a variety of different machining processes.

- With overload torque output and constant torque output capability: machine tool feed (servo motor) the nature of the mechanical load is mainly to overcome the friction of the table and cutting resistance, so the main "constant torque" nature, but also to have a short time torque overload capacity. Like the mainstream servo motor on the market, the overload capacity can reach 3 times or even more.

Constant torque output characteristics of servo motor

Difference between spindle motor and servo motor

- Difference of principle

The spindle motor is a precision asynchronous motor because CNC machine tools have high requirements for motion control, need to have good dynamic characteristics, large speed range and precise position control accuracy, so it needs a special servo motor. The principle is the same as the general squirrel cage motor, the biggest difference between the synchronous servo motor and the asynchronous motor is that the structure of the rotor is different. Synchronous motors have staggered poles on the rotor, and therefore require corresponding detection elements to detect the rotor position. When replacing these detection elements also need to be readjusted.

- Difference of working range

The servo motor works in the constant torque area between the lowest speed and rated speed, while the spindle motor works in the constant power area between the rated speed and the highest speed because to achieve a large speed range, the rated speed of the spindle motor is generally very low.

- Difference in use

The motor is used to detect the speed of the speed generator, the Hall element evenly divided on the circumference of the motor to detect the relative position of the rotor, while the spindle motor is used to detect the motor speed with a position encoder, the motor encoder in addition to the conventional A, B, and R-phase sine cosine signal, there are two C-phase and D-phase sine cosine signal to detect the position of the motor rotor.