What are their Difference: Globe Valve & Butterfly Valve

Valves are pipeline accessories used to open and close pipelines and control flow direction and play an important role in industrial production. There are many types of valves, and their specific functions are also different. Today we will understand the difference between a globe valve and a butterfly valve, let's take a look together.

Globe valve basics

The globe valve is a forced sealing valve and is one of the most widely used valves. The reason why it is so popular is that it is relatively durable due to the small friction between the sealing surfaces during the opening and closing process. The globe valve has not had too much height when open and is easy to maintain, which is very suitable for cutting or regulating, and throttling. Globe valves can be used to control the flow of various types of fluids such as air, water, steam, mud, oil, liquid metal, and radioactive media.

Butterfly valve basics

A butterfly valve, also known as a flap valve, is a regulating valve with a simple structure. Because the butterfly valve is not suitable for close cooperation with the pipe wall, it is only suitable for adjusting the flow rate, and cannot be used to cut off the pipeline. It is often used to adjust the flow rate of the air and flue gas pipeline. The opening and closing part is a circular butterfly plate that rotates with the valve stem to realize the opening and closing action. Butterfly valves can also be designed with regulation, or both cut-off and regulation. At present, butterfly valves are more and more commonly used in low-pressure environments and large/medium-diameter pipelines.

Different structures

The structural form of the globe valve: The body structure of the globe valve includes straight-through type, straight-through type, and right-angle type. The straight-through type is the most common structure, but it has the greatest fluid resistance. The fluid resistance of the straight-line type is small, and it is mostly used for fluids containing solid particles or high viscosity. The right-angle valve body is mostly forged, which is suitable for globe valves with smaller diameters and higher pressure.

The structural form of the butterfly valve: it is mainly composed of a valve body, a valve stem, a butterfly plate, and a sealing ring. The valve body is cylindrical, with a short axial length and a built-in butterfly plate.

Different working principles

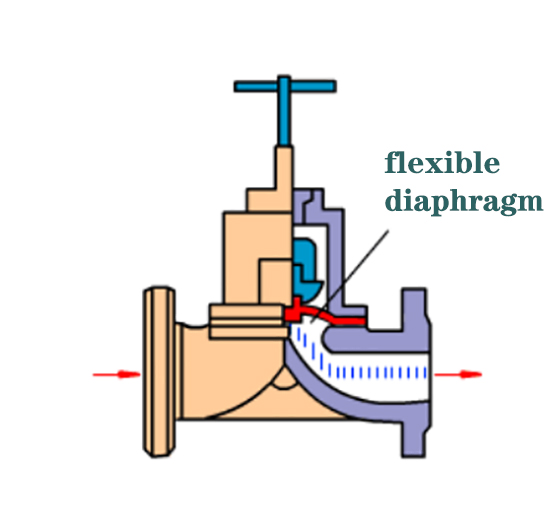

Globe valve principle

Through the pressure of the valve stem, the sealing surface of the disc and the sealing surface of the valve seat are in close contact to prevent the flow of the medium, and the medium flows in one direction, and there is directionality during installation. The opening or closing stroke of the globe valve stem is relatively short, and it has a very reliable cut-off function, and because the change of the valve seat opening is proportional to the stroke of the valve disc, it is very suitable for flow regulation. Therefore, this type of globe valve is very suitable for cutting or regulating and throttling.

Butterfly valve principle

The valve plate of the butterfly valve is small in size and rotates along the center line. The butterfly plate is installed in the diameter direction of the pipeline, and it acts as an opening and closing part and rotates with the valve stem to open, close, and adjust the fluid passage. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0° and 90°. When the rotation reaches 90°, the valve is fully open.

Different advantage

Globe valve advantages:

- The working stroke is small and the opening and closing time is short.

- The sealing surface is not easy to wear and scratch and has good sealing performance.

- When opening and closing, there is no relative sliding between the disc and the sealing surface of the valve body, so the friction between the sealing surfaces is small and the service life is long.

- There is only one sealing surface, the manufacturing process is good, and it is easy to maintain.

- The structure is simple, and the design of the bellows is adopted, so the valve stem can have zero leakage, so maintenance is more convenient.

Advantages of butterfly valves:

- The speed of opening and closing is fast, convenient, and labor-saving, and the fluid resistance is small, so it can be operated frequently.

- When fully open, the effective flow area of the valve seat channel is larger, and the fluid resistance is smaller.

- The opening and closing torque is relatively small. Because the butterfly plates on both sides of the rotating shaft are basically equally affected by the medium, and the direction of the torque is opposite, then the opening and closing are relatively labor-saving.

- A butterfly valve can be used in the conventional saturated steam medium for heating (below 350 degrees).

- The sealing surface material is generally made of rubber or plastic, so the low-pressure sealing performance is good.

- Small size, short structure length, and lightweight, suitable for large-diameter valves.

- It can transport mud, the least liquid is accumulated at the pipe mouth, 90° reciprocating rotation, and the driving torque is small.

- Under low pressure, good sealing can be achieved. Has good fluid control characteristics and shut-off sealing performance.

- The butterfly valve can transport mud, and the liquid accumulated at the mouth of the pipe is the least. The streamlined design of the butterfly plate makes the loss of fluid resistance small, which can be described as an energy-saving product.

Different applications

Globe valve scope of application: The axis of the stem of the globe valve is perpendicular to the sealing surface of the valve seat. The opening or closing stroke of the valve stem is relatively short, and it has a very reliable cut-off action, so the globe valve is very suitable for cut-off or throttling.

Globe valves are suitable for a wide range of pressure and temperature, and are generally used for medium and small-diameter pipelines. At the same time, it can also be used for switch control of low-pressure pipeline media.

The globe valve is relatively tight, but the water flow resistance is relatively large, and the local resistance coefficient is proportional to the pipe diameter, so it is only suitable for pipes with a pipe diameter ≤ 50mm.

Globe valves are easy to manufacture and maintain, have good adjustment performance, and are widely used in pipelines for various media. However, when the fluid passes through the globe valve, there is a change in direction, so the resistance is relatively large, not suitable for pipelines with high viscosity, suspended substances, and materials that are easy to crystallize, and it is also not suitable for vent valves and low-vacuum system valves. Suitable for all kinds of pressurized fluid pipelines, also commonly used in steam and compressed air pipelines.

As one of the most important globe valves, the globe valve plays an important role in the aerospace field. As an important component of aerospace equipment, the globe valve realizes the functions of medium transmission, cut-off, adjustment, and its sealing performance directly affects the safety of aerospace equipment.

Butterfly valve scope of application: Butterfly valves are suitable for flow regulation. The pressure loss of the butterfly valve in the pipeline is relatively large, and the robustness of the pipeline medium pressure on the butterfly plate when it is closed should also be considered. In addition, the limitation of the operating temperature of the elastic seat material at high temperature must also be considered. Usually, in throttling, regulating control and mud medium, short structure length, fast opening, and closing speed (1/4 turn), and low-pressure cut-off (small pressure difference) are required. In this case, a butterfly valve is recommended.

In the case of two-position adjustment, low noise, gasification, or abrasive media, butterfly valves can be selected.

Butterfly valves are suitable for freshwater, sewage, seawater, salt water, steam, natural gas, food, medicine, oil, and various types of valves that require complete sealing, zero leakage in the gas test, high life expectancy, and working temperatures between -10° and 150°. Acid and alkali, are also suitable for pipelines transporting various corrosive and non-corrosive fluid media in engineering systems such as gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting, power generation, and environmental protection, to adjust and cut off the flow of the medium.