Buck Converter vs. Boost Converter

In modern electronics, efficient power conversion is crucial for various applications, ranging from power supplies in consumer electronics to industrial machines. Two of the most commonly used types of DC-DC (Direct Current to Direct Current) converters are the Buck Converter and the Boost Converter. Both are used to convert DC voltage levels, but they do so in different ways and are suited for different applications. Understanding the differences between these two converters is key to selecting the right one for a specific application. ATO Industrial Automation Store offers a variety of buck and boost converters for you to choose from.

What is a Buck Converter?

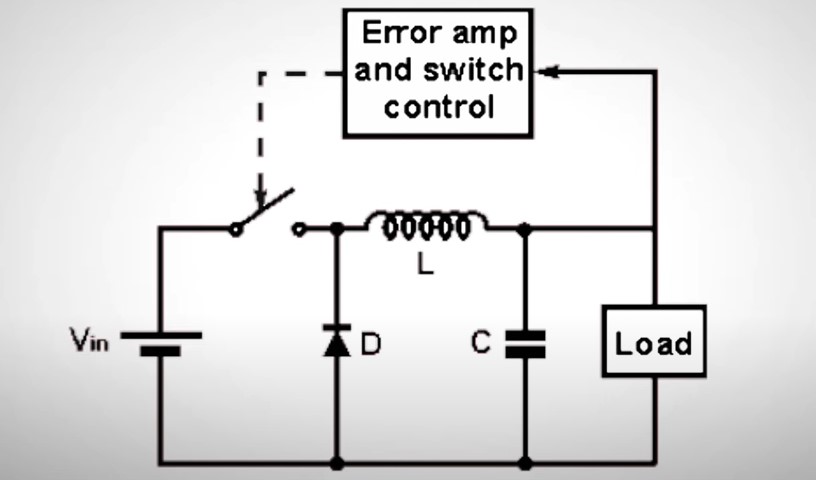

A Buck Converter is a type of DC-DC converter that steps down (reduces) the input voltage to a lower output voltage. The term "buck" is derived from its ability to reduce voltage, similar to how the word "buck" can refer to lowering something in everyday language. It is highly efficient, making it a popular choice for applications requiring a stable lower voltage.

Key Characteristics of Buck Converters:

- Step-down Operation: The buck converter reduces the input voltage to a lower output voltage.

- High Efficiency: Due to its minimal power losses (most of the power is transferred from input to output), a buck converter can achieve efficiencies upwards of 90%.

- Continuous Output: Buck converters maintain a continuous output voltage that is lower than the input.

- Components: Typical components of a buck converter include an inductor, a switch (typically a transistor), a diode, and a capacitor.

- Applications: Power supplies for microcontrollers, laptops, battery chargers, and LED drivers are common examples where buck converters are used.

What is a Boost Converter?

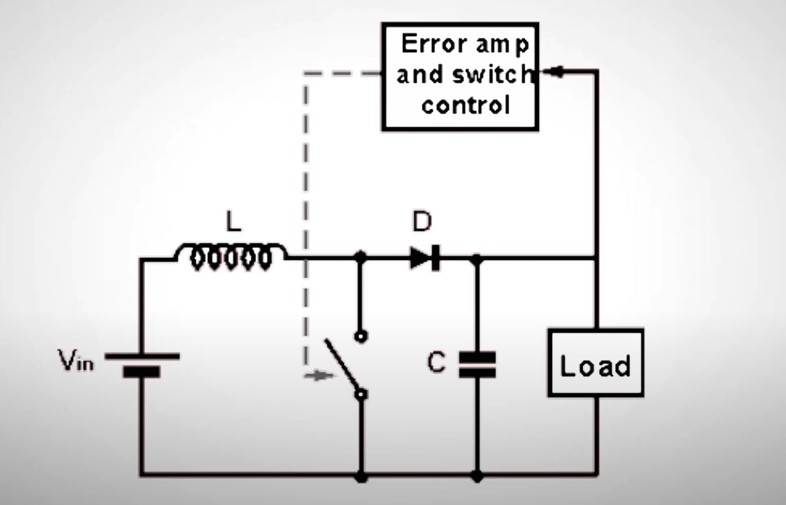

A boost converter is another type of DC-DC converter, but it operates in the opposite direction compared to a buck converter. It steps up (increases) the input voltage to a higher output voltage. The term "boost" refers to its ability to increase the voltage.

Key Characteristics of Buck Converters:

- Step-up Operation: A boost converter increases the input voltage to a higher output voltage.

- Efficiency: Like buck converters, boost converters are highly efficient, often achieving efficiencies greater than 85%.

- Current Limitation: The output current of a boost converter is typically lower than the input current because of the increase in voltage.

- Components: Common components include an inductor, a switch (transistor), a diode, and a capacitor. The configuration is similar to that of a buck converter but optimized for stepping up the voltage.

- Applications: Boost converters are commonly used in battery-powered devices where a higher voltage is needed from a lower voltage source. Examples include powering LEDs, DC motor drives, and portable electronics.

Comparison: Buck vs. Boost Converter

| Feature | Buck Converter | Boost Converter |

| Operation | Steps down voltage | Steps up voltage |

| Efficiency | Typically higher in step-down applications | High but slightly lower than buck converters |

| Input and Output Voltage Relationship | Vout < Vin | Vout > Vin |

| Current Behavior | Output current is higher than input current | Output current is lower than input current |

| Applications | Power supplies for microcontrollers, battery chargers, laptops | Powering LEDs, portable devices, DC motor drivers |

| Component Stress | The components usually deal with lower voltage, reducing stress | Components experience higher stress due to higher output voltage |

Efficiency Considerations

Both buck and boost converters are known for their high efficiency compared to linear regulators. However, the efficiency of each depends on various factors, such as the difference between input and output voltages, the operating frequency, and the quality of the components used.

- Buck converters tend to be more efficient when stepping down voltages because the voltage difference is smaller, and the system's losses are relatively low.

- Boost converters, while efficient, tend to lose more power in scenarios where the voltage boost factor is high, but they are still widely used because of their ability to provide higher voltage from a lower input source.

Choosing Between a Buck and Boost Converter

Choosing between a buck and boost converter depends on the voltage requirements of your application.

Use a Buck Converter if:

- You need to step down the voltage from a higher value to a lower one.

- Your application requires high current at a lower voltage (e.g., powering a low-voltage microprocessor).

- You want maximum efficiency when converting from a higher voltage source to a lower voltage.

Use a Boost Converter if:

- You need to step up the voltage from a lower value to a higher one (e.g., running a device off a 5V battery but needing 12V).

- The application involves battery-powered systems where a higher voltage is needed but you have limited input voltage.

- Powering LEDs, sensors, or other devices that require a higher voltage than the available power supply.

Conclusion

Both buck and boost converters are essential in modern power supply designs. The buck converter is ideal for stepping down voltages efficiently, while the boost converter excels in situations where a higher output voltage is needed from a lower input voltage. Understanding the operational differences, efficiency characteristics, and applications of each type will help you make an informed decision based on your specific power conversion needs.