Hi everyone!

We're working on a project to detect congestion in industrial feeding pipes. These are 75mm bendable pipes used to transport food/feed particles. We're considering using a pressure sensor to detect any rise in pressure that could indicate a blockage.

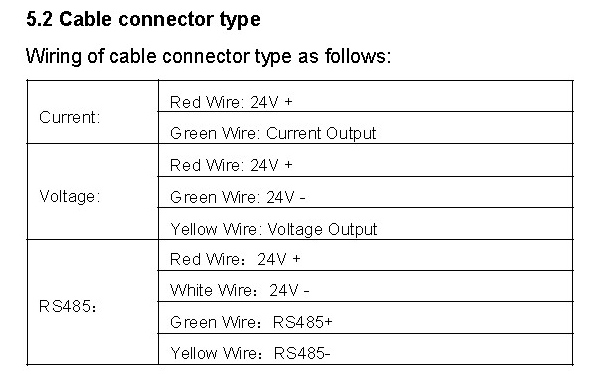

I found a sensor (SKU: ATO-PRES-P300) that might fit the job. It needs to have an RS-485 output signal. Has anyone used a similar setup, or can recommend any alternatives?

We're working on a project to detect congestion in industrial feeding pipes. These are 75mm bendable pipes used to transport food/feed particles. We're considering using a pressure sensor to detect any rise in pressure that could indicate a blockage.

I found a sensor (SKU: ATO-PRES-P300) that might fit the job. It needs to have an RS-485 output signal. Has anyone used a similar setup, or can recommend any alternatives?

0