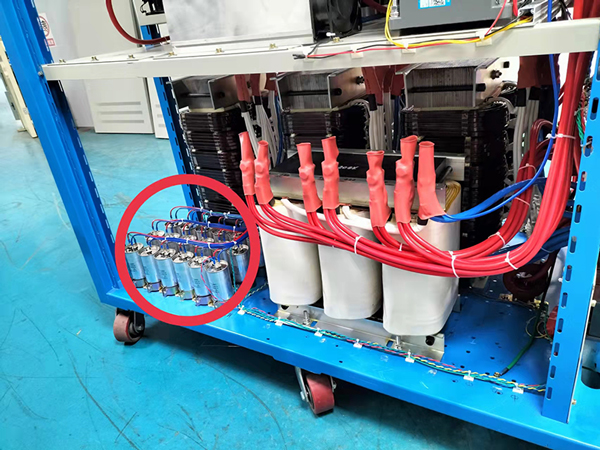

We have an HZ-50-33200 200kVA frequency converter. When we did the calculation for the load we needed we oversized the unit to the 200kVA unit to plenty of current for motor starting. When we are running the plant with full load we are close to 50 amps. We can start the largest motor and have the current jump up to 90 amps then come back down without the unit tripping. We have noticed that once in a while when the load on the largest motor fluctuates we have a trip on the unit which causes the converter to shut down.

What could be causing this, is there some adjustment we can make so that we don’t have this shut down the converter?

What could be causing this, is there some adjustment we can make so that we don’t have this shut down the converter?

0