For stepper motor specification, the operating temperature range for stepper motor should be 0~50℃ while humidity should be 20%~90%RH, and storage temperature should be -20~70℃ while humidity should be 15%~95%RH.

Blog

With global environmental crisis becoming intensified, energy saving and emission reduction has become one target of the automobile industry. Resistance welding and car body manufacturing is inseparable. Depending on its characteristics like wide speed regulation ratio, big rotational torque and high accuracy, resistance welding machines pressed by servo motor plays an important role in welding. It can improve control over welding force and realize accurate control over depth of fusion of welding force and welding points. In addition, servo motor itself has favorable dynamics and it can improve speed from zero to rated speed in several seconds. With its advantages, servo motor has a successful application in resistance welding machine.

Computerized embroidering machine can realize traditional manual embroidery with high speed and high efficiency, and meet the requirement of multi-level, multi-function, unity and perfection which is out of reach of manual embroidery. Servo motor via its advantages plays an important role in various embroidery machines, to make sure the high quality in products.

Marketing of stainless steel servo motors can help producers of the food industry improve design of hygiene machine. Stainless steel servo motor can reduce extra hardware and improve cleanliness, reliability and performance of machines at the same time. The motors adopt smooth and round design which is easy for cleaning, since meat and fluid will not easily gather in surface. The motor is made of grade-300 stainless steel and it will have special treatment after finishing components to remove impurities and further improve corrosive protection performance. In addition, cable outlets of motors are sealed when they leave factory, which can improve product reliability to the utmost extent.

At present, robot has a rapid development especially industrial robot. However, robot should be improved in response speed, accuracy and technological level. Then, what is the key point? The key lies on core part of robot – servo motor.

Water jet, also called high pressure water jet cutting technique, is a special cold cutting and can realize cutting processing of any curves. Now it is widely used in industries like aviation, automobile, stone material, glass, metal, concrete and so on. Servo system takes its own advantages to the application in water jet cutting, which brings a lot of benefits, like high efficiency, low consumption, high cutting precision and high rate of finished products.

It is well known that torque of stepper motor is big in slow speed but it will drop sharply after it reaches above 600RPM, making stepper motor cannot be applied on occasions with high speed motion. Moreover, since positioning defects of stepper motor when it stop working will cause location errors, it cannot meet requirements of modern inkjet printers on high speed and high efficiency any longer. However, servo motor has characteristics like rapid response, high speed and high positioning accuracy, thus modern inkjet printers generally select motors of this kind as cloth feeding motor and small panel control motor, thus forming the situation of the high and medium-end market which centers on alternating servo motor system.

CNC Bending Machine is a machine to process metal plates and it mainly uses hydraulic system to blend panels into different shapes. In view of defects of the hydraulic system of traditional bending machine and characteristics of forming techniques and processes of equipment, it adopts servo drive, servo motor, and gear pump to adjust control system of flow and pressure of hydraulic system, which can reduce system energy consumption and temperature-rising of hydraulic oil, and improve operational reliability of equipment at the same time.

Illustrate the transformation process by taking dedicated servo system of injection molding machine: First, it should replace general asynchronous machine and dosing oil pump of the former system with servo motor and internal gear pump, add pressure transmitter in output direct pipes of oil pump and get rid of proportional pressure valve of the former system and corresponding amplifier board. Pick up analog signals whose pressure and flow are given from computer control of injection molding machine, transform them into 0-10V DC analog pressure signals through comprehensive processing and directly add them in input terminals of system pressure given signals and system flow given signals of servo drives, and connect pressure sensors in exit of oil pump with pressure feedback signal terminal of servo. Servo system can have PI adjustment through connected pressure and flow signals and change output torque and speed of servo motor so as to change output flow Qt and pressure p of oil pump to meet oil pressure and flow required by injection molding machine in various processes.

Fully automatic terminal crimping machine is kind of electromechanical integration machinery which integrates the three major processing procedures of the end of wiring harness, namely, cutting off, flaying. It can process a harness in an average speed of less than 1s and its flaying precision can reach to as high as 0.01ms. To meet the requirement, executive motor plays an important role. Due to its advantages, like high stability, small vibration and high precision, AC servo motor has become a first choice of most fully automatic terminal crimping machine as system executive motors. The AC servo motors are well applied to the wire harness processing of fully automatic terminal crimping machine, which can improve processing efficiency and precision.

Frequency conversion technology is utilized to realize soft start and soft stop. The characteristics of speed up and speed down are utilized to increase the start and stop time of the motor. Take the motor of 1.5KW as an example, the motor employs the slowdown motor with a reduction ratio of 1:10. Through the reversing gear, the motor will change from the revolving movement into the straight line movement. Each revolving will realize one pushing action. When the incense stick goes through the discharging bucket, the stirring device for discharging will be driven with the chain drive organization while the motor is revolving. The material pushing jacket will be filled with incenses and then be extruded outside through pushing. In addition, As to the pressure(discharging quantity), the operator can adjust the revolving eccentric wheel to change the journey of the material pushing jacket and increase its discharging space, thus achieving the pressure change. Completing the whole process only needs about 0.4s, then one incense stick is finished. The VFD has been debugged for incense stick manufacturing, so as to reach the manufacturing requirements thoroughly.

Loading trolley, uncoiling machine, board swaging device, six-layer straightening machine, tracking shearing system, conveying and lifting work platform, double-layer pneumatic layout shelf, hydraulic system, electrical control system. The overall system adopts the VFD, PLC, touch screen, rotary encoder and other components to constitute the automatic control system of the production line. Under the premise of giving consideration to both horizontal shearing precision and manufacturing efficiency, through utilizing the high-speed counting function of the PLC and the speed regulating and controlling function of the VFD, so as to control the starting, operating, speed reducing, crawling and accurate stopping of the straightening roll and pressing roll effectively, thus realizing the high-efficient and automatic cutting to length of the metal plate.

In the entire manufacturing process of the concrete pile, molding on the centrifuge is the most vital step. This process includes: Cloth distribution, second level transition, compacting three stages. Different stages have different requirements to the revolving speed and time of the tubular pipe. In addition, the tubular pipes of different wall thickness and length will have different requirements to the revolving speed and time of the three stages. This requires the VFD to be able to regulate the working stage of the motor according to the different types of concrete piles. It will operate different speed and time at different stages to ensure the product quality of the concrete pile.

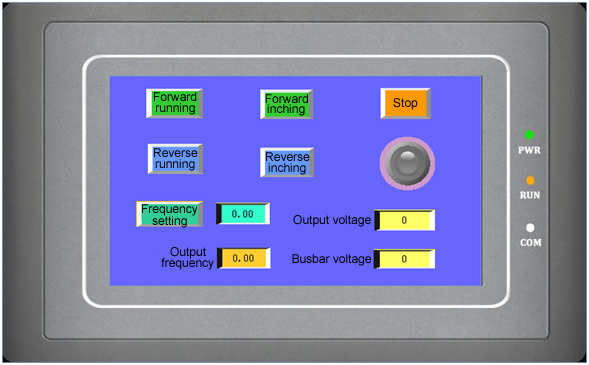

VFD and the display control HMI touchscreen is communicating through MODBUS, so as to realize the stopping, frequency setting and status monitoring and other functions of the VFD through the HMI touchscreen.

The wire-cut EDM is to utilize the metal linear tool electrode (or named as wire electrode) to process workpieces with the principle of impulsive discharge to erode the metals. High speed wire-cut EDM is applied in the processing of the metal pieces with high precision, complicated shape, especially the mould and so on.

Because the induction motor has incomparable advantages: Simple and solid structure, cheap price, and easy maintenance.  So using the means of VFD dragging three-phase induction motor replaces the means of traditional speed regulating, can solve the problem of high failure rate of the tower crane fundamentally. Moreover, it has advanced technology and significant energy saving effect. It is the ideal transmission controlling device of the tower crane.

So using the means of VFD dragging three-phase induction motor replaces the means of traditional speed regulating, can solve the problem of high failure rate of the tower crane fundamentally. Moreover, it has advanced technology and significant energy saving effect. It is the ideal transmission controlling device of the tower crane.

The overhead crane is a kind of hoisting machinery with quite extensive application in the industrial and mining enterprise. Its operating organism is constituted by three basically independent dragging systems, which are respectively the cart dragging system, dolly dragging system and hook dragging system. This article ATO will take the practical application of VFD for overhead crane improvement in thermal power plant as the example, illustrating the application and improvement scheme of VFD for the overhead crane comprehensively.

The VFD speed control system regards the network pressure as the control object. The pressure transmitter changes the pressure in the air storage tank into the electrical signal to send into the PID regulator inside the VFD, so as to compare with the pressure setting value. Then calculation will be made according to the set PID control mode based on the difference value. The control signal will be generated to control the output signal and inverter frequency of the VFD, thus adjusting the revolving speed of the induction motor, so as to maintain the practical pressure to be always as the setting pressure.

According to the manufacturing technology of the hydroextractor, the multi-speed functional control of the VFD can be used. The hydroextractor with VFD control system belongs to the approximate constant torque load with big inertia. Therefore, the system requirements can be reached by configuring braking unit and braking resistor on the basis of selecting the AC converter. The built-in braking unit of the30hp VFD and below can not only save space, but also save the cost.

This article ATO summarizes how to apply and debug the VFD for the circular knitting machine in one textile mill. ATO chooses the non-inductive vector VFD. It adopts current vector control, its precise control as well as the characteristics of low-frequency stability and large torque, realizing the functions of big starting torque, stable operation, quick stop and so on of the circular knitting machine.