Axial Fan vs. Centrifugal Fan

In industrial and commercial ventilation systems, choosing the right type of fan is critical to ensuring system efficiency and performance. Axial fan and centrifugal fan are two of the most common fan types, and they differ significantly in their design, operating principles, performance characteristics, and application scenarios. This blog will delve into the differences between these two types of fans to help you make an informed decision when choosing a fan.

Working Principles of Axial Fan and Centrifugal Fan

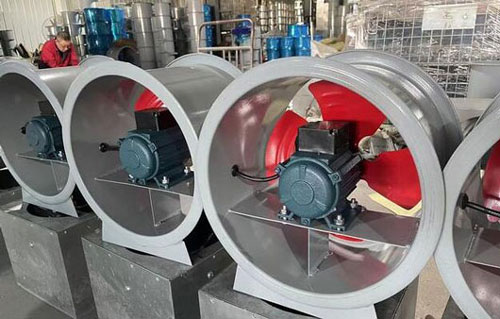

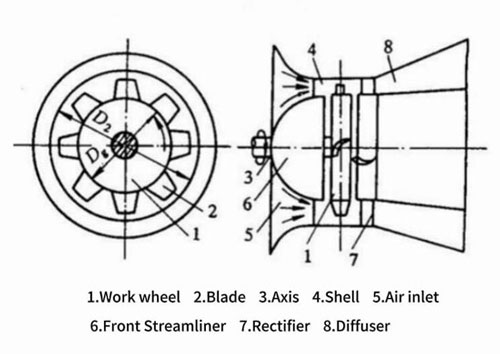

Working Principle of Axial Fan

The working principle of an axial fan is based on aerodynamic principles, and its core component is a set of rotating blades. When the blades are rotated by a motor, air enters the fan at the inlet, flows in the direction of the fan's axis, and exits at the outlet. The fan is designed so that the direction of air flow is parallel to the fan axis, hence the name “axial flow”.

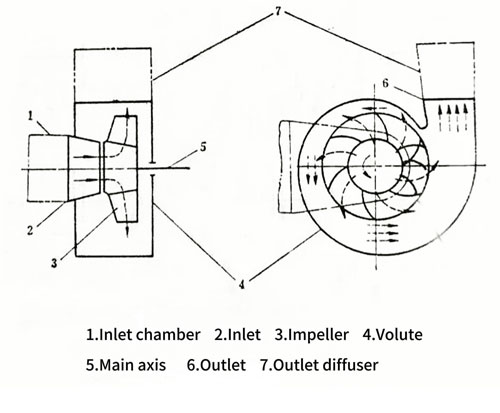

Working Principle of Centrifugal Fan

Centrifugal fans work differently in that they utilize centrifugal force generated by a rotating impeller to move air. When air enters a centrifugal fan, the high speed rotation of the impeller causes the air to gain kinetic and pressure energy, which is then expelled from the fan in a radial direction. These fans are designed so that the direction of air flow is perpendicular to the fan axis, hence the name “centrifugal”.

Performance Characteristics of Axial Fan and Centrifugal Fan

Performance Characteristics of Axial Fan

- High Efficiency: Axial fans can achieve high efficiency under certain operating conditions.

- Compact: Axial fans are usually very compact in design and are suitable for space-constrained installations.

- Low Noise: Axial fans often use special blade designs and materials to minimize the noise generated during operation.

- Easy to Maintain: Axial fans are relatively simple in structure and maintenance and repair work is relatively easy to carry out.

- Energy Efficient: The high efficiency of axial fans helps to reduce energy consumption and operating costs.

Performance Characteristics of Centrifugal Fan

- High Pressure Generation: Centrifugal fans are capable of generating high pressures and are suitable for applications requiring high pressure boosts.

- High Flow Handling Capacity: Centrifugal fans can handle larger flows and are suitable for applications with high airflow requirements.

- Stability: Centrifugal fans exhibit high stability and reliability during operation.

- Adaptability: Centrifugal fans can adapt to a variety of operating environments, including high temperature, high pressure and corrosive environments.

- Cost Effectiveness: Centrifugal fans may have a higher initial investment, but their long-term operating costs are lower, making them highly cost-effective.

Advantages and Disadvantages of Axial Versus Centrifugal Fans

Compared with the axial fan and centrifugal fan, each has its own advantages and disadvantages, they play an important role in different fields, the axial fan has a cooling effect is obvious, energy saving and low-consumption advantages, centrifugal fan applicability is more extensive, running up the performance is stable, ventilation time is short, the whole is made of steel plate material, the surface using the spraying process, should not be rust corrosion resistance is good.

Compared with centrifugal fans, axial fans have a relatively simple structure and are easier to install. It can usually be installed directly in the duct without the need for complex foundations and support structures. This gives axial fans a great advantage in situations where space is limited, such as ventilation ducts and air conditioning systems. Centrifugal fans, on the other hand, have a relatively complex structure, are larger and heavier. This makes it more difficult to be transported and installed, requiring more space and support structures.

And axial fans are usually more compact, smaller and lighter. This makes it easier to transport and install, and saves installation space.

In addition, axial fans are able to provide a large air volume, which makes them suitable for applications that require large amounts of air circulation. For example, in a ventilation system, an axial fan can quickly remove the dirty air from the room and introduce fresh air to keep the indoor air fresh.

Most importantly, axial fans have relatively low operating costs. It is usually less powerful, consumes less electricity and is easier to maintain. This allows axial fans to save a lot of energy and maintenance costs in the long run. Centrifugal fans, on the other hand, are usually more powerful, consume more electricity and are more complex to maintain. This makes centrifugal fans require higher energy and maintenance costs in long-term operation.

Compared to axial fans, centrifugal fans are capable of generating higher air pressures and are suitable for applications where high air pressures are required. For example, in industrial ventilation systems, centrifugal fans can overcome the resistance of longer ventilation ducts and transport air over longer distances. Axial fans, on the other hand, have a relatively low air pressure and are not suitable for applications requiring high air pressure. For example, in long-distance ventilation ducts, axial fans may not be able to overcome duct resistance, resulting in poor ventilation.

At the same time, centrifugal fans produce relatively little noise during operation, especially when advanced noise reduction technology is used. This makes centrifugal fans widely used in some occasions with high noise requirements, such as hospitals, schools and office buildings. While the axial flow fan will produce large noise during operation, especially at high speed. This may cause a certain amount of noise pollution to the surrounding environment, and it is necessary to take corresponding noise reduction measures. What's more, the airflow stability of centrifugal fans is not easily influenced by external factors. This enables centrifugal fans to maintain stable ventilation in a variety of complex environments. In contrast, the airflow stability of axial fans is poorer and easily affected by external factors. For example, the ventilation effect of axial fans may be affected in situations where the wind direction changes considerably.

Application Scenarios for Axial and Centrifugal Fans

Application Scenarios for Axial Fans

- Industrial Ventilation: In order to ensure air quality and the comfort of workers, the factory's axial fan will be used to provide necessary ventilation and improve indoor air quality.

- HVAC Systems: In commercial buildings and residences, axial fans are used to regulate air flow and provide cooling and heating.

- Cooling Water Towers: In power plants and industrial facilities, axial fans are used in cooling water towers to improve cooling efficiency.

- Air Purification: In air purification systems, axial fans are used to filter and clean air.

Application Scenarios for Centrifugal Fans

- High Pressure Ventilation Systems: Centrifugal fans are ideal in ventilation systems that require high pressure lift, such as ventilation of high-rise buildings and mine ventilation.

- Large Industrial Facilities: In large industrial facilities, such as petrochemical plants, power plants, etc., centrifugal fans are used to handle large volumes of air movement.

- Commercial Buildings: In commercial buildings such as shopping malls, hotels, office buildings, etc., centrifugal fans are used to provide the necessary ventilation and air conditioning.

- Environmental Control: Centrifugal fans provide consistent performance in applications where precise control of air flow and pressure is required, such as laboratories, hospitals, etc.

Conclusion

Axial and centrifugal fans each have their own advantages and limitations, and the choice of which fan to use depends on the specific application requirements, budget and system design. Whether in industrial production, built environment control or other areas, the right choice of fan will have a significant impact on the efficiency and performance of your system. ATO Industrial Automation provides you with a comparison of the two types of equipment, and by taking an in-depth look at how they work, their performance characteristics, application scenarios, and their cost-effectiveness, you can select the most appropriate type of fan for your project.