Autotransformer: Working Principle and Advantages

Autotransformer refers to a transformer whose windings are primary and secondary on the same winding, with the primary and secondary windings directly connected in series and self-coupled. According to the structure, it can be further divided into adjustable pressure type and fixed type. A regular transformer transfers energy through electromagnetic coupling between the primary and secondary coils. There is no direct electrical connection between the primary and secondary coils, while an autotransformer has a direct electrical connection between the primary and secondary coils. Its low-voltage coil is a part of the high-voltage coil. ATO online store will explain how autotransformers work and their advantages in power systems and electronic devices.

Working Principle

When two or more coils are wound around a closed iron core and an AC power supply is applied to one coil (i.e. the primary coil), alternating current flows through the coil, which generates an alternating magnetic field in the iron core. The alternating main magnetic flux generates its own induced electromotive force in the primary coil, while the other coil (i.e. the secondary coil) induces mutual inductance electromotive force. By changing the ratio of turns between the primary and secondary coils, the terminal voltage of the primary and secondary coils can be changed to achieve voltage transformation. Because the primary and secondary coils are directly connected, there is a risk of cross level leakage. So it cannot be used as a transformer for running lights.

- An autotransformer is a special transformer where the output and input share a set of coils. Different taps are used to achieve voltage rise and fall. The tap voltage of the part with fewer than the shared coils decreases, while the tap voltage of the part with more than the shared coils increases.

- Actually, the principle is the same as that of a regular transformer, except that its original coil is its secondary coil. A typical transformer is a primary coil on the left that generates voltage through electromagnetic induction on the secondary coil on the right, while a step down autotransformer affects itself.

- An autotransformer is a transformer with only one winding. When used as a step-down transformer, a portion of the wire turns are extracted from the winding as the secondary winding; When used as a step-up transformer, the applied voltage is only applied to a portion of the winding turns. The part of the winding that belongs to both the primary and secondary windings is usually called the common winding, and the rest of the autotransformer is called the series winding. Compared with ordinary transformers, autotransformers of the same capacity not only have smaller size but also higher efficiency, and the larger the transformer capacity, the higher the voltage. This advantage becomes more prominent. Therefore, with the development of power systems, the improvement of voltage levels, and the increase of transmission capacity, autotransformers have been widely used due to their large capacity, low losses, and low cost.

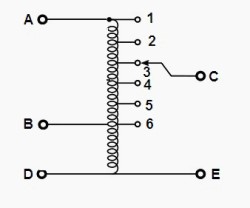

The circuit diagram of the autotransformer is shown in the right figure. When a single-phase AC power supply is connected between terminals A and D, and the output is taken from terminals C and E, the autotransformer will operate as a step-down transformer.

Advantages

Autotransformers have the following advantages compared to ordinary double winding transformers:

- Low material consumption and low cost. Because the amount of silicon steel sheets and copper wires used in electrical transformers is related to the rated induced potential and rated current of the winding, that is, to the capacity of the winding, the capacity of the autotransformer winding is reduced, the material consumption is also reduced, and the cost is also low.

- Less loss leads to higher efficiency. Due to the reduced usage of copper wire and silicon steel sheets, the copper and iron losses of autotransformers are reduced compared to double winding transformers at the same current density and magnetic flux density, resulting in higher efficiency.

- Easy to transport and install. Because it is lighter in weight, smaller in size, and occupies less space than double winding transformers of the same capacity.

- Improved the maximum manufacturing capacity of transformers. The maximum manufacturing capacity of transformers is generally limited by transportation conditions. Under the same transportation conditions, the capacity of autotransformers can be larger than that of double winding transformers.

In summary, autotransformers play an important role in the fields of power engineering and electronic equipment with their unique design and advantages, providing effective solutions for energy transmission and electrical equipment.