AC Generator vs. DC Generator

Electricity is one of the most dominant sources of energy in modern society. Generators are mechanical devices that convert other forms of energy into electrical energy, and there are huge differences between alternators and DC generators, despite their similar names. These two types of generators provide completely different results. They both provide current, but the final current is different in the way they move, their mechanisms, their design and their use. Here, ATO will explain the differences between AC generators and DC generators.

What is AC Generator?

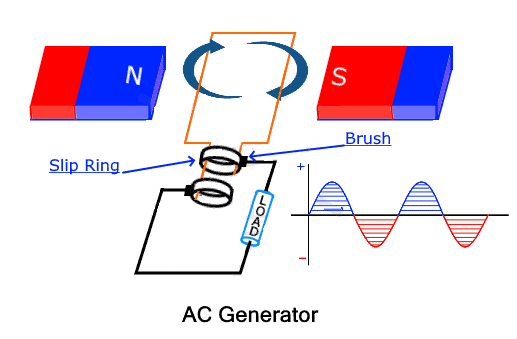

An alternator current generator is a generator that converts mechanical energy into alternating current electrical energy. It is a generator designed to produce alternating current at a frequency of 50 or 60 Hz. The current induced in the armature is supplied to the circuit through the slip ring. Slip rings are two separate conductive rings connected to each terminal of the armature. These rings power the circuit through sliding contacts called brushes. The ring always rotates with the armature when the brushes remain stationary.

What is DC Generator?

DC generator is also a generator that converts mechanical energy into DC electrical energy. It is also called a generator. It produces pulsating direct current that does not change direction. The induced current in the rotating armature conductors is alternating in nature and is converted to direct current using an open loop commutator. The commutator supplies current from the rotating armature to the stationary circuit while maintaining the direction of the supplied current.

Differences between AC generator and DC generator

Different structure:

- AC synchronous generator: Single phase AC synchronous generator usually consists of stator, rotor, end cover and bearing.

- Direct current generator: Direct-current generator is divided into two parts, the stator and the rotor.

Different working principle

- Direct current generator: In order to make the brushless DC generator rotate, the control unit must first determine the position of the generator rotor sensed by the Hall sensor, and then determine the order of the power transistors in the inverter according to the stator winding. AH, BH and CH in the inverter are called upper arm power transistors. ) and al, bl, cl (these are called lower arm power transistors), which make current flow through the motor coils in turn, creating a forward (or reverse) rotating magnetic field and interacting with the rotor magnets, allowing the motor to operate clockwise/reverse Clock rotation.

- Alternator current generator: It uses the principle of electromagnetic induction to convert the mechanical energy of the prime mover into electrical energy output. A synchronous generator consists of a stator and a rotor. The stator is the armature that produces electricity, and the rotor is the magnetic pole. The stator consists of an armature core, a three-phase winding with uniform discharge, a frame and an end cover. The rotor is usually a hidden pole type, consisting of an excitation winding, an iron core and a shaft, a guard ring, a center ring, etc. The excitation winding of the rotor generates a nearly sinusoidal magnetic field (called the rotor magnetic field) through a DC current, and its effective excitation is the stator. The magnetic flux intersects the stationary armature winding. When the rotor turns, the magnetic field of the rotor turns with the same start and with each rotation. The magnetic wire cuts off each phase winding of the stator in turn, and generates a three-phase alternating current potential in the three-phase stator winding. When the generator runs with a symmetrical load, the three-phase armature currents are combined to generate a rotating magnetic field at synchronous speed. The interaction of the stator magnetic field with the rotor magnetic field will generate a braking torque. From the steam/steam/gas turbine, the mechanical torque input overcomes the braking torque and works.

Differences in use and maintenance

The output voltage produced by an AC synchronous generator is called an alternator. The normal frequency for alternators in the US, Europe and Japan is 60Hz. This output voltage differs in time and magnitude. DC generators produce a stable output voltage and are suitable for powering large motors. DC generators are mainly used to power large electric motors, while alternators are used for small electric motors. You can power appliances in your home such as food blenders, appliances, etc. with the help of AC.

AC and DC generators are huge when it comes to maintenance. DC generators require frequent maintenance and are less reliable, while alternators require little maintenance and are more reliable.

The comparison between AC and DC generators concluded that AC generators are more durable, more reliable and simpler in design than DC generators. However, DC has no frequency, so the speed of the prime mover doesn't affect it, but it does require frequent maintenance, which adds to its overall cost.