Torque Sensor

Reaction Torque Sensor, Dual Flange, 20 Nm/100 Nm/5000 Nm to 10000 Nm

Reaction Torque Sensor for Torque Wrench Calibration, 5-200 Nm

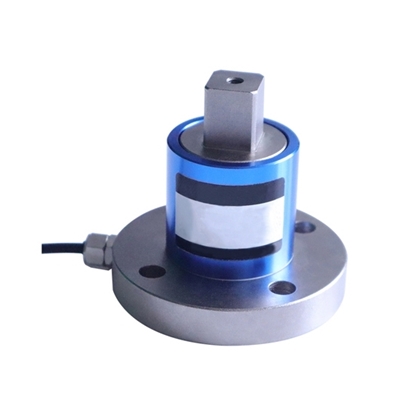

Reaction Torque Sensor, Flange to Square Drive, 2/10/30/50/100/200 Nm

Micro Reaction Torque Sensor for Static Torque, 0.5-150 Nm

Static Strain Gauge Torque Sensor, Shaft Type, 100Nm-5000Nm

Rotary Torque Sensor, Non-Contact, Shaft to Shaft, 0.05-300000 Nm

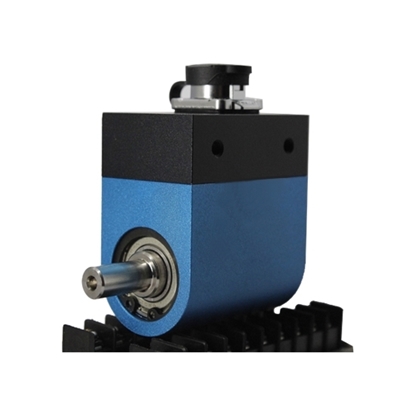

Micro Rotary Torque Sensor for Dynamic Torque Measurement, 0.1-5 Nm

Digital Rotary Torque Sensor, 0.1/5/300/1000 Nm to 10000 Nm

Rotary Torque Sensor, Dual Flange, 20-5000 Nm

Rotary Torque Sensor, Non-Contact, 50-50000 Nm

Static Torque Sensor, 0-100 Nm

Static Torque Sensor, Disc Type, 0-10 Nm

Static Torque Sensor, Disc Type, 0-50 Nm

Force Torque Sensor, Flange, 0-20/30/50/100/200 Nm

Static Torque Transducer, Dual Flange, 0 -1/2/3/5 Nm

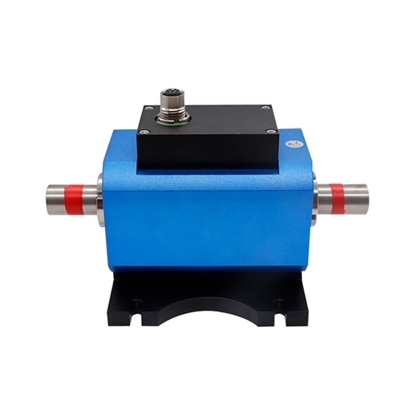

Small Dynamic Torque Transducer, Non Contact, 5/10/50/100/200/500 Nm

Signal Amplifier for Torque Sensor, RS485/0-5V/0-10V/4-20mA

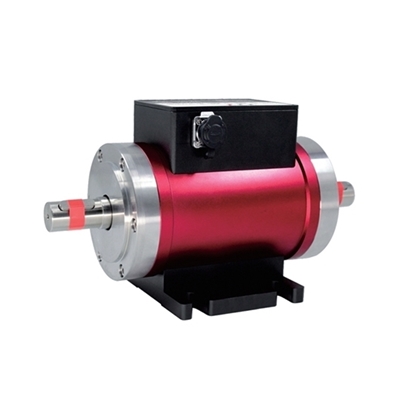

Rotary Motor Torque Sensor, Micro Type, 0.1-5 Nm

Dynamic Torque Sensor for Motor Torque/RPM, 50-10000 Nm

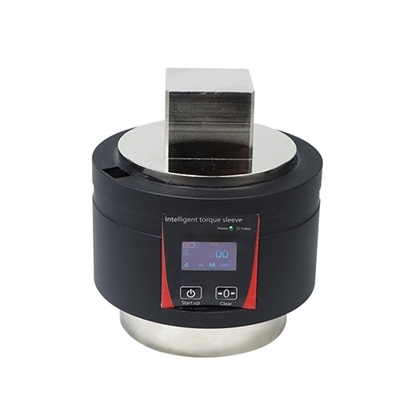

Digital Rotary Torque Sensor with Smart Sleeve, 500-3000 Nm

Torque sensors are divided into dynamic torque sensors and static torque sensors. The static torque sensor can also be called reaction torque sensor, while the dynamic torque sensor can also be called non-contact torque sensor or rotary torque sensor. Torque sensors are used for detecting the perception of torque on various rotating or non-rotating mechanical components. The torque sensor converts the physical changes of torsion into precise electrical signals. The torque sensor has the advantages of high precision, fast frequency response, good reliability and long life.

The torque sensor applications are:

- AC/DC motor, servo motor, stepper motor.

- The automobile engine, diesel engine, steering gear, the overall rigid torsion of the vehicle body and the control and detection of other parts processing.

- Electric (hand) actuators, automatic opening and closing control of various valves.

- Control and monitoring of oil extraction and refining processes, monitoring of fire (water) power generation equipment, ore screening control, and monitoring of wind power generation equipment.

- Torque life test of various materials.

- Detect the torque, power and rotary speed of various motors, pumps, windlasses, rotary machines, CNC and automatic machine tools.

- Can be used to test and calibrate viscometer and electric (pneumatic, hydraulic) torque wrench.

What are the Types of Torque Sensor?

Strain Gauge Torque Sensor (Reaction Torque Sensor)

Strain gauge torque sensor adopts strain electric measurement technology. A strain gauge is attached to the elastic shaft to form a measuring bridge. When the elastic shaft is slightly deformed by torque, the resistance value of the bridge will change, and the change of strain bridge resistance will change into the change of electrical signal to achieve torque measurement. The sensor completes the following information conversion, such as the sensor consists of elastic shaft, measuring bridge, instrument amplifier and interface circuit.

Strain gauge torque sensor adopts strain electric measurement technology. A strain gauge is attached to the elastic shaft to form a measuring bridge. When the elastic shaft is slightly deformed by torque, the resistance value of the bridge will change, and the change of strain bridge resistance will change into the change of electrical signal to achieve torque measurement. The sensor completes the following information conversion, such as the sensor consists of elastic shaft, measuring bridge, instrument amplifier and interface circuit.

Non-Contact Torque Sensor

The input shaft and output shaft of the non-contact torque sensor are connected by a torsion bar, the input shaft is provided with splines, and the output shaft is provided with a keyway. When the torsion bar is twisted by the rotational moment of the steering wheel, the relative position between the splines on the input shaft and the keyway on the output shaft is changed. The relative displacement of the spline and the keyway changes by an amount equal to the twist of the torsion bar, which changes the magnetic induction on the spline. The change of the magnetic induction is converted into a voltage signal through the coil.

The input shaft and output shaft of the non-contact torque sensor are connected by a torsion bar, the input shaft is provided with splines, and the output shaft is provided with a keyway. When the torsion bar is twisted by the rotational moment of the steering wheel, the relative position between the splines on the input shaft and the keyway on the output shaft is changed. The relative displacement of the spline and the keyway changes by an amount equal to the twist of the torsion bar, which changes the magnetic induction on the spline. The change of the magnetic induction is converted into a voltage signal through the coil.

Rotary Torque Sensor

Rotary torque sensors can be used in the manufacture of viscometers, electric (pneumatic, hydraulic) torque wrenches. It have the advantages of high precision, fast frequency response, good reliability, and long life. Using strain gauge electrical measurement technology, a strain bridge is formed on the elastic shaft, and the electrical signal of the elastic shaft being twisted can be measured by supplying power to the strain bridge. After the strain signal is amplified, it is converted into a frequency signal proportional to the torsional strain after pressure/frequency conversion.

Rotary torque sensors can be used in the manufacture of viscometers, electric (pneumatic, hydraulic) torque wrenches. It have the advantages of high precision, fast frequency response, good reliability, and long life. Using strain gauge electrical measurement technology, a strain bridge is formed on the elastic shaft, and the electrical signal of the elastic shaft being twisted can be measured by supplying power to the strain bridge. After the strain signal is amplified, it is converted into a frequency signal proportional to the torsional strain after pressure/frequency conversion.

How to Calibrate a Torque Sensor?

- Calibration preparation: Prepare the calibration tools (weight components, torsion joints (for folding testing machines), enamel discs (for automatic torque machines), rotary testers, torsion handles).

- Turn on the industrial control host, open the test software, and ensure that the pressure sensor and the motion card are connected stably, and the numerical value is within the range of error (0.01gf.cm-0.03gf).

- Assemble the auxiliary connectors.

- Open the software to select the corresponding range of the sensor, then open the calibration sensor interface, and clear the value when the sensor has no load.

- Select the appropriate weight according to the range of the sensor (for the sensor with a small range, choose a small weight, and for a large range, choose a larger weight. For example, 2N.m choose 200g, 100g weight, 50N.m choose 500g, 1kg weight code), tie the weight to one end of the connecting piece, and hang it on one end of the pulley through the rope along the groove of the standard piece to keep the contact state stable without external force.

- On the software calibration interface, click Allow Calibration, enter the torque value of the calibration weight (gravity * force arm), and click OK.

- Wind the weight in another direction to check the reverse force value. If the difference is large (>0.5gf.cm), take the average value of the positive and negative force values.

- Record the calibration data.

- The calibration cycle is normally 1 year. If it is repaired or adjusted during use, it needs to be re-calibrated.

If you want to know more about how to calibrate a rotary torque sensor, please check:

Tips for Installing Torque Sensor

- Torque sensor can be installed horizontally or vertically.

- Power equipment, sensors, load equipment should be installed on a stable basis to avoid excessive vibration, otherwise data instability may occur, reduce the measurement accuracy, or even damage the sensor.

- Connect with elastic pin coupling or rigid coupling.

- The concentricity of the axis of power equipment, sensors and load equipment should be less than φ 0.05mm.