Strain Gauge

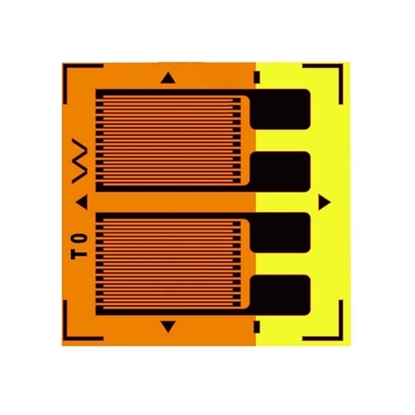

90 Degree Resistance Strain Gauge

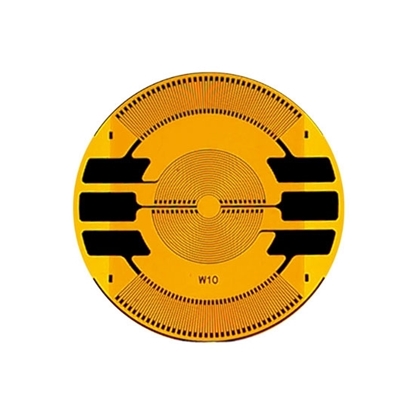

Diaphragm Strain Gauge for Pressure Transducer

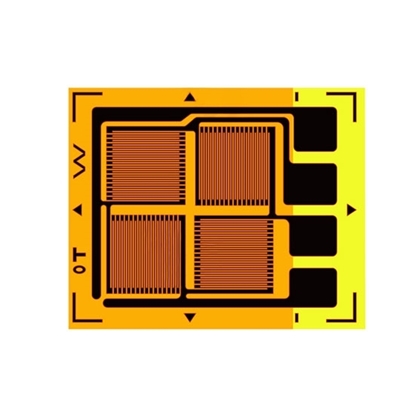

Full Bridge Resistance Strain Gauge

Half Bridge Shear Strain Gauge

Half Bridge Uniaxial Strain Gauge

Uniaxial Shear Resistance Strain Gauge

What is a strain gauge?

Strain gauges are object strain used to measure dynamic sensors. Indirectly using strain measurement, they can also be used for stress measurement and load cells.

When the stress inside the structure under test changes, the strain gauge feels the deformation simultaneously, and the deformation is transmitted to the vibrating string through the front and rear end holders to transform it into a change in the stress of the vibrating string, thus changing the vibration frequency of the vibrating string. The electromagnetic coil excites the vibrating chord and measures its vibration frequency. The frequency signal is transmitted to the reading device through the cable, and the internal strain in the structure under test can be measured. At the same time, the temperature value of the buried point can be measured simultaneously.

ATO resistance strain gages are mainly composed of four parts: substrate, sensitive grid, adhesive, and protective layer, which are etched with a thickness of 0.005mm metal foil. The sensitive grid is very thin and can better reflect the deformation of the surface of the components, thus the measurement accuracy is high. Strain gauges are widely used in various types of scales, industrial force measurement, stress analysis tests and high temperature melt pressure sensors.

Working principle of resistance strain gauges

The working principle of resistance strain gage is based on the strain effect, where the resistance value of a metal wire is related to the length and cross-sectional area of the wire in addition to the nature of the material.

When a wire is glued to a component, the length and cross-sectional area of the wire change along with the component when it is deformed by a force, resulting in a change in resistance.

What is shear strain gauge?

Shear strain means that in the case of simple shear, the material is subjected to a force F which is two forces of equal magnitude and opposite direction parallel to the cross section A0, and under this shear force, the material will be deflected. The tangent of the deflection angle θ is defined as the shear strain γ: i.e. γ = tanθ. When the shear strain is small enough, γ = θ and the corresponding shear stress is τ = F/S.

How to choose the resistance value of the strain gauge?

The resistance value of the strain gauge is selected according to the requirements of the test instrument for the resistance value of the strain gauge and the sensitivity of the measurement strain, as well as the test conditions. For example, when doing stress testing, in order to match the resistance strain gauge, the 1200 strain gauge is generally used: for the sensor, in order to improve its stability or output sensitivity, high resistance (such as 3502, 502, 10002 or even higher) is often used. , sometimes considering the signal-to-noise ratio, the power consumption is also selected with a high resistance value strain gauge.

The thin sensitive grid reflects the deformation of the element surface and is designed for precision pressure sensors. Strain gauges are inexpensive and available in a variety of models.

How to choose the type of strain gauge?

The type of strain gauge is selected according to the purpose of strain measurement, the material of the test piece and its stress state as well as the requirements of measurement accuracy. For example, if the strain gauge is used as a sensitive element of a force measurement sensor at room temperature, the foil strain gauge with zero drift and minimal creep is used; if the output sensitivity of the sensor is required to be large, the semiconductor strain gauge is used; if it is used for dynamic strain measurement, the foil strain gauge is usually chosen.

How to choose the temperature self-compensation and elastic film self-compensation of the strain gauge?

According to the working temperature of the strain gauge and the material of the specimen, as well as the measurement accuracy requirements, the temperature self-compensating or elastic film self-compensating strain gauge working at this temperature is selected. For example, for ordinary steel or spring steel, a temperature self-compensating strain gauge with a linear expansion coefficient of 11X10^-6°C should be used; for aluminum alloy materials, a temperature self-compensating strain gauge with a linear expansion coefficient of 23X10^-6°C should be used. strain gauge.

How to choose the size of the strain gauge?

Select the size of the strain gauge according to the material and stress conditions of the specimen, as well as the area where the strain gauge is allowed to be pasted. For large strain gages, it is recommended to use strain gages with a grid length of 3-6mm. If the stress concentration area of the specimen or the allowable bonding surface is small, it is recommended to use a strain gauge with a grid length of ≤1 mm. A strain gauge with a longer grid length has the advantages of easy bonding, wiring, and good heat dissipation. There is a certain improvement in the performance of the strain gauge. The smaller the size of the strain gage, the higher the requirements for the paste quality and the relatively poor heat dissipation. Therefore, on the premise of ensuring the measurement accuracy and sufficient installation area, it is appropriate to select a strain gage with a larger grid length.

Strain gauge applications

- Aerospace

Strain gauges are connected to Wheatstone bridge circuits and their application areas include on-board signal conditioning units, excitation power supplies, and telemetry required to read field measurement data.

- Cable bridges

Instrumentation of bridges is used to verify design parameters, evaluate the performance of new technologies used in bridge construction, verify and control the construction process and subsequent performance monitoring.

Well-equipped bridges can alert authorities of impending failures so that preventive measures can be taken. The selection of the appropriate sensor type, technology, measurement range and its location on the bridge is important to optimize costs and make the best use of the instrumentation.

It is necessary to regularly monitor any deformation of the bridge, as it can lead to fatal accidents. Strain gauge technology is used for real time monitoring of large bridges to make the detection more accurate.

- Railway monitoring

Strain gauges have a long history of use in rail safety. It is used to measure stress and strain on rails. Strain gauges measure axial tension or compression without impacting the rail. In emergency situations, strain gauges can provide warnings for early maintenance to minimize the impact on rail traffic.