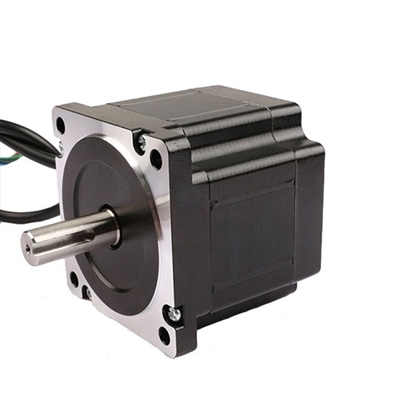

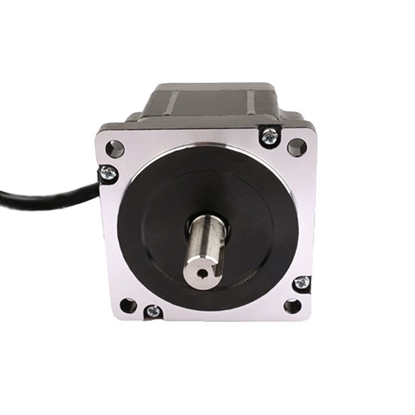

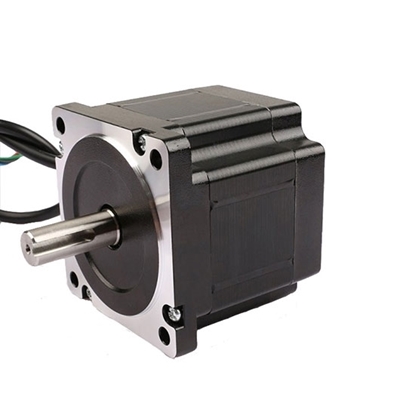

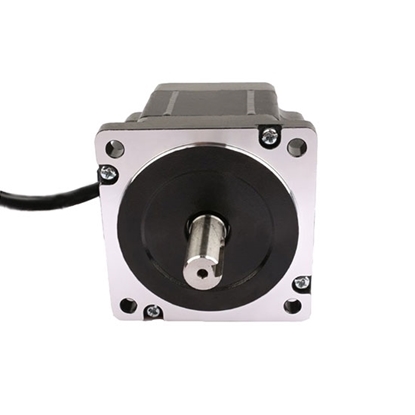

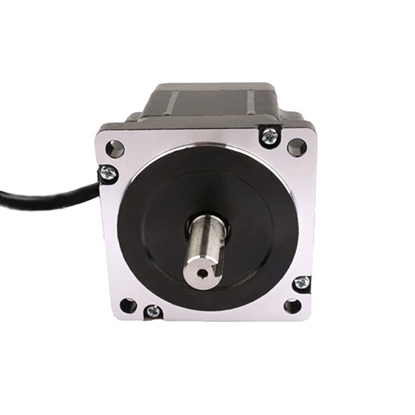

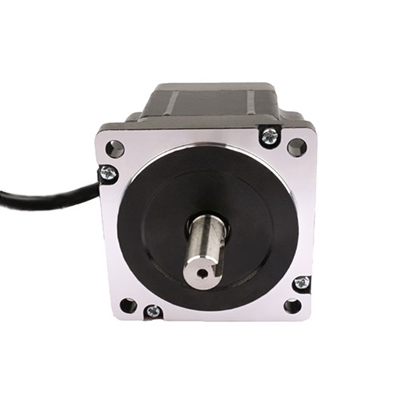

NEMA 34 Stepper Motors

Nema 34 2-phase Stepper Motor, 6A, 1.8 degree, 4 wires

Nema 34 3-phase Stepper Motor, 1.3A, 1.2 degree, 6 wires

Nema 34 3-phase Stepper Motor, 3.3A, 1.2 degree, 6 wires

Nema 34 3-phase Stepper Motor, 3A, 1.2 degree, 6 wires

Nema 34 Stepper Motor bipolar, 3A, 1.8 degree, 2 phase 4 wires

Nema 34 Stepper Motor Bipolar, 4.5A, 1.8 degree, 4 wires

Nema 34 Stepper Motor, 1.1A, 1.2 degree, 3 phase 6 wires

Nema 34 Stepper Motor, 1.8 degree, 3A, 2 phase 4 wires

Nema 34 Stepper Motor, 3.3A, 1.2 degree, 3 phase 6 wires

Nema 34 Stepper Motor, 3A, 1.2 degree, 3 phase 6 wires

Nema 34 Stepper Motor, 4.5A, 1.8 degree, 2 phase 4 wires

As a kind of most suitable motor in CNC field, Nema 34 stepper motors with high torque are available here. ATO provides two series of Nema 34 stepper motor: One is 2-phase stepper motor with 1.8° step angle, and another is 3-phase with 1.2° step angle. The holding torque differs from 2.8Nm to 12Nm for your selection. Buy a Nema 34 stepper motor on ATO.com online store and believe you can get one as you desired.

What is Nema 34 hybrid stepper motor?

Nema 34 hybrid stepping motor is a stepper motor designed by combining the advantages of permanent magnet and reactive. It is divided into 2 phase, 3 phase and 5 phase. The 2 phase stepper angle is generally 1.8 degrees, the three phase stepping angle is generally 1.2 degrees, and the five phase stepping angle is generally 0.72 degrees.

The rotor of the hybrid stepping motor itself is magnetic, so the torque generated under the same stator current is larger than that of the reactive stepping motor, and its step angle is usually smaller. Therefore, economical CNC machine tools generally need to use hybrid stepping motors. However, the structure of the hybrid rotor is more complicated, the rotor inertia is large, and its rapidity is lower than that of the reactive stepper motor.

Nema 34 stepper motor features

- Large output torque and high speed.

- The motor generates little heat, low noise and high efficiency.

- The high-speed stop is smooth and fast, the operation is stable without zero-speed oscillation, and the vibration and noise are small.

- Fast response speed, suitable for occasions with frequent start and stop.

Nema 34 stepper motor working principle

The structure of the hybrid stepper motor is different from that of the reactive stepper motor. The stator and the rotor of the reactive stepper motor are both integrated, while the stator and the rotor of the hybrid motor are divided into two sections as shown in the figure below. There are also small teeth on the surface.

The two slots of the stator are not in place, and the windings are arranged on them. The above shows a 2 phase 4-pole motor, in which 1, 3, 5, and 7 are the magnetic poles of the A-phase winding, and 2, 4, 6, and 8 are the magnetic poles of the B-phase winding. Adjacent pole windings of each phase are wound in opposite directions to produce the closed magnetic circuit shown in the X, Y view in the above figure.

The B phase is similar to the A phase. The two tooth slots of the rotor are staggered by half a tooth pitch, and the middle is connected by a ring-shaped permanent magnet, and the magnetic poles of the teeth of the two rotors are opposite. According to the same principle of the reactive motor, as long as the motor is energized in the order of A-B-A-B-A or A-B-A-B-A, the stepper motor can continuously rotate counterclockwise or clockwise.

Obviously, all the teeth on the same segment of the rotor piece have the same polarity, while the polarities of the rotor pieces of two different segments are opposite. The biggest difference between the hybrid stepper motor and the reactive stepper motor is that when the magnetized permanent magnetic material is demagnetized, there will be oscillation points and out-of-step regions.