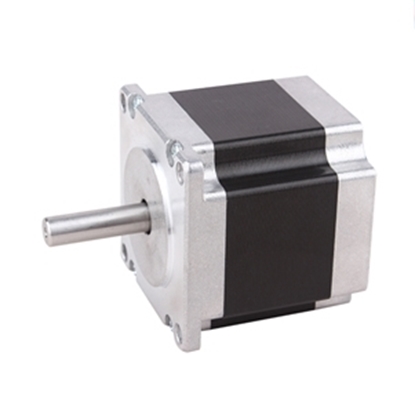

NEMA 23 Stepper Motors

Nema 23 Bipolar Stepper Motor, 1A, 1.8 degree, 4 wires

Nema 23 Bipolar Stepper Motor, 2A, 1.8 degree, 4 wires

Nema 23 Bipolar Stepper Motor, 3A, 1.8 degree, 4 wires

Nema 23 Stepper Motor Bipolar, 1.8 degree, 1.5A, 2 phase 4 wires

Nema 23 Stepper Motor Bipolar, 1.8 degree, 2A, 2 phase 4 wires

Nema 23 Stepper Motor Bipolar, 1.8 degree, 3A, 2 phase 4 wires

Nema 23 Stepper motor, 1A, 1.8 degree, 2 phase 6 wires

Nema 23 Stepper Motor, 2.8A, 1.8 degree, 2 phase 4 wires

Nema 23 Stepper motor, 2A, 1.8 degree, 2 phase 6 wires

Nema 23 Stepper Motor, 3A, 1.8° step angle, 2 phase 6 wires

Nema 23 Stepper Motor, 4.2A, 1.8 degree, 2 phase 4 wires

Nema 23 Stepper Motor is one of widely used stepper motors, with an installation size of 2.3 x 2.3 inch (57 x 57 mm). Our Nema 23 hybrid stepper motor has a 1.8° step angle (200 steps/revolution), with the holding torque from 0.4N·m to 3.0N·m. This high torque stepper motor comes in a range of lengths and 8mm or 6.35mm shaft to meet your requirements. It can be driven at the desired speed without loss step. Suitable for 3D printer, robot arm, CNC router, sewing machine, etc.

Nema 23 stepper motor working principle

When current flows through the stator windings, the stator windings generate a vector magnetic field. The magnetic field will drive the rotation angle of the rotor, so that the direction of a pair of magnetic fields of the rotor is consistent with the direction of the magnetic field of the stator. When the vector magnetic field of the stator rotates by an angle. The rotor also rotates an angle with this magnetic field. Each time an electrical pulse is input, the stepper motor rotates an angle and moves forward one step. The angular displacement it outputs is proportional to the number of input pulses, and the rotational speed is proportional to the pulse frequency. Change the order in which the windings are energized and the motor will reverse. Therefore, the rotation of the stepper motor can be controlled by controlling the number of pulses, the frequency and the power-on sequence of each phase winding of the stepper motor.

How to select a stepper motor?

- Stepper motor Torque

Select a right stepper motor according to the required torque. Roughly speaking, if the required torque is below 0.8N.m, choose Nema 8, 11, 14, 17 stepper motor. If the torque is about 1N.m, it is more appropriate to choose the Nema 23 stepper motor. When required torque is higher, it is necessary to choose a Nema 34 stepper motor. - Stepper motor rotary speed

The output torque of the stepper motor is inversely proportional to the rotational speed. That is to say, the output torque of the stepper motor is large at low speed, and the torque in the high-speed rotation state is small. Of course, some working conditions require high-speed motors, so it is necessary to measure the coil resistance, inductance and other indicators of the stepping motor. Select a motor with a slightly smaller inductance, as a high-speed motor, a larger output torque can be obtained. - No-load starting frequency of stepper motor

The no-load starting frequency of a stepper motor is an important indicator for purchasing. If it is required to start and stop frequently in an instant, and the speed is around 1000 rpm, it usually needs to be accelerated to start. If you need to start directly to achieve high-speed operation, it is best to choose a reactive or permanent magnet motor. The idle frequency of these stepper motors is relatively high. - Phase of stepper motor

Stepper motors with different phases have different working effects. The more the number of phases, the smaller the step angle, and the smaller the vibration during operation. In most cases, 2 phase motors are used more often. In the high-speed and high-torque working environment, it is more practical to choose a 3 phase stepper motor.