Load Cell

Single Point Load Cell, 300g/1kg/3kg/ 10kg/60kg/100kg/200kg to 500kg

Parallel Beam Load Cell, Single Point, 4kg/8kg/10kg/15kg to 30kg

Digital Load Cell, RS232/RS485, 3kg to 350kg

Strain Gauge Load Cell, S type, 5kg/20kg/30kg/500kg to 7 ton

Strain Gauge Load Cell, S type, 5kg/50kg/1000kg/3 ton to 20 ton

S Beam Load Cell, 50kg-5 ton, Analog/Digital/RS485 Output

S Type Load Cell for Tension and Compression, Stainless Steel, 200kg-5 ton

Micro Load Cell, S type, 1kg/2kg/3kg/10kg to 50kg

Micro Load Cell, S Type, 5N/500N/1000N, 1kg/10kg/30kg/200kg

Tension and Compression Load Cell, 100kg/2 ton to 20 ton

Tension and Compression Load Cell, 1 kg - 500 kg

Miniature Tension and Compression Load Cell 3kg/20kg/100kg to 500kg

Tension and Compression Load Cell, Threaded Inline, 0-20kN

Tension Load Cell for Crane, 2 ton/5 ton/30 ton/50 ton to 70 ton

Tension Sensor for Wire Rope, Three Pulley, 2kg-100kg

Tension Load Cell, 10 ton/30 ton/50 ton/100 ton to 200 ton

Compression Load Cell, 300kg/1000kg/25 ton/50 ton to 100 ton

Tension/Compression Load Cell, Low Profile, 500kg/30 ton to 100 ton

Compression Load Cell, 300kg/500kg/2 ton/10 ton to 30 ton

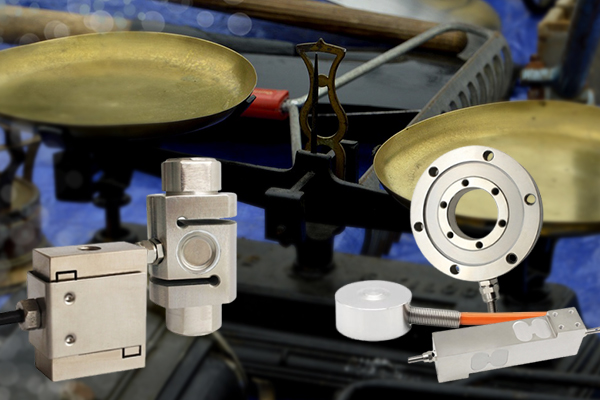

Precision Low Profile Load Cell, Spoke Type, 0-100KN

A load cell is a device that converts a mass signal into a measurable electrical output. The load cell sensor should first consider the actual working environment in which the sensor is located, this point is crucial to the correct choice of load cell, it is related to the sensor's work properly its safety and service life, and even the reliability and safety of the entire scale. In general, it can connect to a special digital panel meter to obtain readings directly, or connect to a load cell transmitter/amplifier to output standard signal (0~5V, 0~10V, 0~±10V, 4~20mA, or RS485). In the main technical indicators of the load cell basic concepts and evaluation methods, the old and new national standards have qualitative differences. There are mainly S-type, cantilever type, spoke type, plate ring type, membrane box type, bridge type, column cylinder type, and other styles.

Load Cell Principle of Operation

The resistance strain load cell is based on the principle that the elastomer (elastic element, sensitive beam) under the action of external force produces elastic deformation, so that the resistance strain gauges pasted on the surface of it (conversion element) also produce deformation, after the deformation of the resistance strain gauges, its resistance will change (increase or decrease), and then by the corresponding measurement circuit to convert this resistance change into an electrical signal (voltage or current), thus completing the transformation of the external force into an electrical signal, which is a signal that can be converted into an electrical signal (voltage or current). Thus completing the process of transforming the external force into an electrical signal. It can be seen that the resistance strain gauge, elastomer, and detection circuit are indispensable parts of the resistance strain load cell.

Classification of Load Cells

Load cell according to the conversion method is divided into photoelectric, hydraulic, capacitive, vibration, gyroscope, resistance strain type, and other categories, resistance strain type is the most widely used.

Photoelectric load cell including grating type and code disk type two. Grating type sensor using the grating formed by Moore's stripes to convert the angular displacement into a photoelectric signal. Grating has two pieces, one for the fixed grating, the other is mounted on the dial axis of the moving grating. The measured object added to the load-bearing table rotates the dial axis through the force-transferring lever system, driving the moving grating to rotate and move Moore's stripes along with it. With the use of photocells, conversion circuits, and display instruments, you can calculate the number of Moore's stripes moved, measuring the size of the angle of rotation, to determine and read out the mass of the measured object.

Code plate load cell code plate (symbol plate) is a piece of transparent glass mounted on the dial axis, with a certain coding method coded in black and white code. When the object to be measured on the load-bearing table rotates the dial shaft using a force transmitting lever, the code disk also turns through a certain angle. The photoelectric cell will receive the light signal through the dial and convert it into an electrical signal, which is then digitally processed by the circuit and finally displayed on the monitor to represent the measured mass. Photoelectric load cells were once mainly used in electromechanical scales.

Hydraulic load cell when subjected to the measured object gravity P, the pressure of the hydraulic oil increases, and the degree of increase is proportional to the P. The pressure of the hydraulic oil increases when the measured object gravity P, the pressure of the hydraulic oil increases. The increase in pressure is proportional to P. Measuring the increase in pressure determines the mass of the object to be measured. Hydraulic load cell structure is simple and solid, the measurement range is large, but the accuracy is generally not more than 1/100.

The capacitive load cell is the use of capacitor oscillation circuit oscillation frequency f and the pole plate spacing d proportional to the work of the relationship. There are two pole plates, one is fixed and the other is movable. In the load-bearing platform loaded with the measured object, the plate spring deflection, the distance between the two pole plates changes, and the oscillation frequency of the circuit also changes. The frequency change can be measured to find out the mass of the measured object on the load table. Capacitive sensors consume less power, have low cost, accuracy of 1/200 ~ 1/500.

Resistance, inductance, and capacitance are three major types of passive components in electronics, capacitive sensors measure changes in the change in capacitance of the sensor, which is essentially a capacitor with variable parameters.

The rotor of the gyroscopic load cell is mounted in the inner frame and rotates steadily around the X-axis with an angular velocity ω. The inner frame is connected to the outer frame by a bearing and can be tilted around the horizontal axis Y. The outer frame is connected to the outer frame by a universal coupling. The outer frame is connected to the machine base by a universal coupling and rotates about the vertical axis Z. The rotor axis (X-axis) is the axis of rotation of the load cell. The rotor shaft (X-axis) remains horizontal when not subjected to external forces. One end of the rotor shaft tilts and rotates around the vertical axis Z when an external force (P/2) is applied. The angular velocity ω is proportional to the external force P/2. By measuring ω through the method of detecting frequency, the size of the external force can be found, and then the mass of the object to be measured that generates this force. Gyroscope type sensor response time (5 seconds), no hysteresis phenomenon, good temperature characteristics (3ppm), vibration effect is small, frequency measurement accuracy and precision, so you can get a high resolution (1/100000) and high measurement accuracy (1/30,000 ~ 1/60,000).

The resistive strain load cell utilizes the principle that its resistance changes with the deformation of the resistive strain gauge. It is mainly composed of 4 parts: elastic element, resistance strain gauge, measuring circuit, and transmission cable.

The structure of the plate ring load cell has the advantages of clear stress flow distribution, high output sensitivity, elastomer as a whole, simple structure, stable stress state, easy to process, and so on. Currently, the sensor production also accounts for a large proportion of the design formula for this structure of the sensor is not perfect. Because the strain calculation of this elastomer is more complex, usually in the design as a circular elastomer for estimation. Especially for 1t and the following range of the plate ring load cell design calculation error is greater, and often there is a large nonlinear error. Plate and ring load cell use and characteristics: compact structure, good protection performance. High precision, good long-term stability. Suitable for hook scales, electromechanical scales, and other force measurements.

The digital load cell is a kind of force-electricity conversion device that can change gravity into an electric signal, which mainly refers to a new type of sensor integrating resistance strain load cell, electronic amplifier (AMC for short), analog-to-digital conversion technology (ADC for short) and microprocessor (MCU for short). The development of digital load cell and digital measuring instrument technology has gradually become a new favorite in the field of weighing technology, which is easy and efficient to debug, and adapt to the field of strong ability and other advantages are emerging in the field.

S-type load cell is the most common type of sensor, mainly used to measure the tensile force and pressure between the solids, general people also call it a tensile pressure sensor, because of its appearance like the S shape, so customarily also known as the S-type load cell, this sensor is made of alloy steel, rubber sealing protection treatment, easy to install, easy to use, suitable for crane scales, dosage scales, machine scales, and other electronic force measurement weighing system.

As an indispensable core component in modern industry and daily life, load cells are leading the way in the continuous innovation of measurement and control technology. Whether it is in manufacturing, logistics, retail, medical, etc., load cells meet the needs of diverse applications with high precision, stability, and reliability. This catalog introduces many types of load cells in detail, including strain gauge, column, digital, etc. It also provides technical specifications, application scenarios, and installation guides for each model of ATO's high-quality load cells, helping users quickly select the product that best suits their needs.

With the integration of IoT and automation technology, load cells are also accelerating in the direction of intelligence, laying the foundation for the realization of intelligent manufacturing and precise management. We look forward to helping our customers improve production efficiency, reduce operating costs, and maintain an edge in the fiercely competitive market through these innovative products. If you are interested in any of the products in the catalog or need more technical support, please feel free to contact our professional team. We will be happy to provide you with one-stop solutions and explore the future of weighing technology with you.

Filter by:

Clear All