Gas Sensor

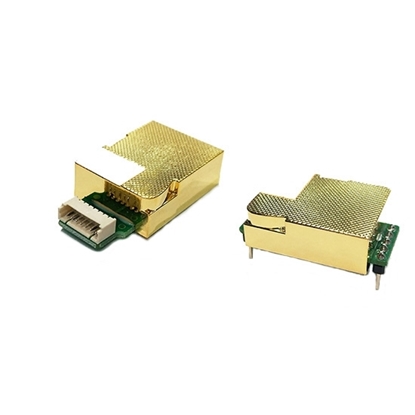

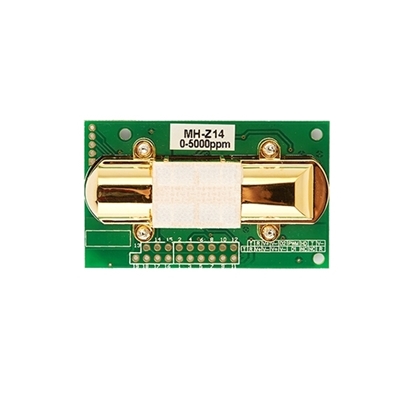

Infrared CO2 Sensor Module, UART/ PWM output

NDIR CO2 Gas Sensor, 0 to 2000/ 5000 ppm

NDIR CO2 Sensor Module, 0 to 10000 ppm

NDIR CO2 Sensor Module, 400-2000/ 5000/ 10000 ppm

Industrial NDIR CO2 Sensor for HVAC, 0 to 2000/ 6000 ppm

Carbon Dioxide (CO2) Sensor for Home, 0 to 2000 ppm

Infrared Carbon Dioxide (CO2) Transmitter, RS485, 0-50000ppm

Oxygen (O2) Gas Sensor, 0~100%

Electrochemical Oxygen Sensor, 0~25%vol

Fluorescent Oxygen Sensor, 0-300mbar, 0-25%

High Pressure Oxygen Sensor, 0.8-7 bar, 0-100%

Ultrasonic Oxygen Sensor, 0-10L/min, 21-95.6%

Ultrasonic Oxygen Sensor, 0-15L/min, 21-95.6%

Oxygen Gas Sensor/Transmitter, RS485/4-20mA/0-5V

Ozone (O3) Detection Sensor, 10ppb to 1000ppb

Smoke Gas Sensor, 200ppm to 10000ppm

Smoke Sensor Module, TTL Output

Alcohol Gas Sensor, 25ppm to 500ppm

Gas Sensor, Methane(CH4)/ Hydrogen(H2)/ Carbon Monoxide(CO)/ TVOC

Methane (CH4) Sensor, 0 to 5% Vol

A gas sensor is a transducer that converts the volume fraction of a gas into a corresponding electrical signal. The probe head conditions the gas sample through the gas sensor, which usually includes filtering out impurities and interfering gases, drying or cooling and processing the instrument display section.

Key Characteristics of Gas Sensors

- Stability: Stability refers to the sensor's ability to maintain a consistent response over its operational lifetime, determined by zero drift and interval drift. Zero drift is the change in sensor output response when no target gas is present, while interval drift refers to the decline in sensor output when continuously exposed to the target gas. Ideally, a sensor should exhibit less than 10% zero drift per year under continuous operation.

- Sensitivity: Sensitivity is the ratio of sensor output change to the change in detected gas concentration. It primarily depends on the sensor's structural technology. Most gas sensors use biochemical, electrochemical, physical, or optical detection principles. The chosen sensing technology must have sufficient sensitivity to detect gas levels at Threshold Limit Values (TLV) or Lower Explosive Limits (LEL).

- Selectivity: Also known as cross-sensitivity, selectivity is determined by measuring the sensor's response to interfering gases. This response is compared to that of the target gas at a specific concentration. Selectivity is critical for detecting multiple gases, as cross-sensitivity affects measurement repeatability and reliability. An ideal sensor should have high sensitivity and strong selectivity.

- Corrosion Resistance: Corrosion resistance refers to the sensor’s ability to withstand high concentrations of the target gas. When large gas leaks occur, the sensor probe should endure concentrations 10-20 times higher than expected. After returning to normal conditions, sensor drift and zero-point correction should be minimal.

Types of Gas Sensors

Gas sensors can be classified based on working principles, detection methods, application fields, and sensing materials. Below are the common types:

Based on Working Principles

- Electrochemical Gas Sensors: Detect gases through chemical reactions that generate electrical signals. Used for toxic and combustible gas detection (e.g., CO, H₂S, O₂ sensors).

- Semiconductor Gas Sensors: Use metal oxide semiconductors (MOS) to detect gas concentrations based on conductivity changes. Suitable for VOC, CO, and CH₄ detection.

- Infrared (NDIR) Gas Sensors: Use infrared absorption to measure gas concentration, ideal for CO₂, CH₄, and refrigerants.

- Catalytic Gas Sensors: Detect combustible gases by oxidation on a catalytic bead, commonly used for methane and hydrogen detection.

- Photoionization Detectors (PID): Detect volatile organic compounds (VOCs) by ionizing gas molecules with UV light.

- Laser-Based Gas Sensors: Use laser absorption spectroscopy (TDLAS) to detect gases like CO₂, CH₄, and NH₃ with high precision.

- Acoustic (Ultrasonic) Gas Sensors: Detect gas leaks and flow rates based on sound wave propagation changes.

Based on Detection Method

- Fixed Gas Sensors: Installed in industrial sites, warehouses, and confined spaces for continuous monitoring.

- Portable Gas Sensors: Handheld devices for field inspections, safety monitoring, and personal protection.

- Wireless Gas Sensors: Connected via IoT or Bluetooth for remote monitoring.

Based on Detected Gases

- Toxic Gas Sensors: Detect harmful gases like CO, H₂S, SO₂, NH₃, Cl₂, and NO₂.

- Combustible Gas Sensors: Measure flammable gases like CH₄, H₂, C₂H₂, and C₃H₈.

- Oxygen Sensors: Monitor O₂ levels in medical, industrial, and confined spaces.

- VOC Sensors: Detect formaldehyde, benzene, and other volatile organic compounds.

- CO₂ Sensors: Used in air quality control, greenhouses, and HVAC systems.

Based on Sensing Materials

- Metal Oxide Semiconductor (MOS) Sensors: Durable but affected by humidity and temperature.

- Electrochemical Sensors: High selectivity and low power consumption, commonly used in safety applications.

- Optical Sensors (NDIR, Laser): High precision and stability, best for CO₂ and CH₄ detection.

- Catalytic Sensors: Effective for flammable gas detection in explosive environments.

How to Choose Gas Sensor

Measurement Object and Measurement Environment

The type of gas sensor is determined based on the measurement object and environment. Before conducting a specific measurement, the first step is to consider the working principle of the sensor. This requires analyzing multiple factors because even for the same physical quantity, different sensor principles may be available. Choosing the most suitable sensor depends on the characteristics of the measured object and the conditions of use. The following aspects should be considered:

Measurement range

- Size requirements for the measurement location

- Contact or non-contact measurement method

- Signal output method (wired or wireless)

- Sensor source (domestic or imported), cost, or self-development feasibility

Once these factors are considered, the type of sensor can be selected, followed by evaluating its specific performance parameters.

Sensitivity Selection

In the linear range of a gas sensor, higher sensitivity is generally preferred, as it provides a larger output signal corresponding to the measured changes, facilitating signal processing. However, higher sensitivity can also introduce external noise, which may be amplified and reduce measurement accuracy. Therefore, the sensor should have a high signal-to-noise ratio (SNR) to minimize interference.

Sensitivity also has directionality:

- If the measured quantity is a single vector with a strict direction requirement, a sensor with low sensitivity in other directions should be chosen.

- If the measured quantity is multidimensional, the cross-sensitivity should be minimized to ensure accuracy.

Response Characteristics (Response Time)

The frequency response of a sensor determines the range of measurable frequencies. Within this range, the gas sensor should maintain accurate measurements without distortion. However, sensors always have some response delay, and shorter delays are preferred.

- Higher frequency response allows a broader signal detection range.

- Mechanical inertia in some sensor structures limits high-frequency measurements.

- In dynamic measurements, response characteristics should match the signal type (steady-state, transient, or random) to avoid large errors.

Linear Range

The linear range of a gas sensor is the range where output is proportional to input, meaning sensitivity remains constant.

- A wider linear range means a larger measurement range while maintaining accuracy.

- When selecting a sensor, ensuring the range meets requirements is the first priority.

- In reality, no sensor has perfect linearity.

- If high accuracy is not required, sensors with minor non-linearity errors can be treated as linear within a certain range, making measurement more convenient.