Shopping cart

Search

Encoder

Incremental Rotary Encoder, Shaft, 1000 ppr

$155.24

SKU: ATO-IRE-1000PS

Optical rotary encoder adopts stainless steel solid shaft. The diameter of shaft is 6mm. 1000 ppr incremental rotary encoder has shell diameter 38mm, working voltage 5VDC/ 8-30VDC, operating temperature -30~+85℃ (-22~+185℉), cable edge output mode, high reliability, high quality and 6 output mode.

Incremental Rotary Encoder, Shaft, 1024 ppr

$189.63

SKU: ATO-IRE-1024PS

Favourable price optical rotary encoder adopts stainless steel square flange, Φ15mm stainless steel shaft and Φ58mm shell. Incremental rotary encoder with 1024 ppr resolution has high reliability, good antijamming capability and long service life. It can be widely used in automation control and measurement systems.

Incremental Rotary Encoder, Shaft, 1200 ppr

$152.96

SKU: ATO-IRE-1200PS

Cheap price optical rotary encoder adopts stainless steel shaft, with 8mm shaft diameter, 52mm shell diameter, 1200 ppr resolution, high reliability, high quality. Incremental rotary encoder has optional output modes and working voltage to choose. The maximum shaft speed can be 5000 rpm.

Incremental Rotary Encoder, Shaft, 1600 ppr

$183.87

SKU: ATO-IRE-1600PS

Inexpensive optical rotary encoder adopts stainless steel shaft, high reliability, high quality, several output modes to choose, manufacturer direct sale. Incremental encoder 1600 ppr with 8mm shaft diameter, 52mm shell diameter, 5000 rpm maximum shaft speed can be used for injection molding machines, robots and CNC machine centers.

Incremental Rotary Encoder, Shaft, 2000 ppr

$155.24

SKU: ATO-IRE-2000PS

Low priced optical rotary encoder with stainless steel shaft has 6mm shaft diameter, 38mm shell diameter, 2000 ppr resolution, A/B/Z signal, optional output mode, optional voltage DC 5V/8-30V. Incremental rotary encoder can be used for workbenches, printing and packaging machinery.

Incremental Rotary Encoder, Shaft, 2500 ppr

$161.59

SKU: ATO-IRE-2500PS

Cheap incremental optical encoder adopts stainless steel shaft Φ10mm, high reliability, high resolution 2500 ppr, high quality, shell diameter 58mm, several output modes to choose, manufacturer direct sale.

Incremental Rotary Encoder, Shaft, 3000 ppr

$237.46

SKU: ATO-IRE-3000PS

Low cost incremental optical encoder adopts stainless steel shaft with diameter 10mm, shell diameter 58mm, high reliability, high resolution 3000 ppr, high quality, operating temperature -30~+85℃ (-22~+185℉), several output modes to choose, manufacturer direct sale.

Incremental Rotary Encoder, Shaft, 400 ppr

$142.22

SKU: ATO-IRE-400PS

Low cost 400 ppr rotary encoder adopts stainless steel shaft, high quality, several output modes to choose, manufacturer direct sale. Incremental rotary encoder has 6mm shaft diameter and 38mm shell diameter.

Incremental Rotary Encoder, Shaft, 500 ppr

$142.22

SKU: ATO-IRE-500PS

Favourable price optical encoder has 6mm diameter stainless steel shaft, 38mm shell diameter, 500 ppr resolution, high reliability, high quality, several output modes to choose, manufacturer direct sale.

Incremental Rotary Encoder, Shaft, 5000 ppr

$299.95

SKU: ATO-IRE-5000PS

Favourable price optical shaft encoder adopts stainless steel shaft, high reliability, high resolution 5000 ppr, high quality, several output modes to choose, manufacturer direct sale. Incremental rotary encoder has 52mm shell diameter and 8mm shaft diameter.

Incremental Rotary Encoder, Shaft, 600 ppr

$181.59

SKU: ATO-IRE-600PS

Cheap optical rotary encoder adopts stainless steel shaft, square flange and plug edge output mode. The diameter of shaft is 15mm. The diameter of shell is 58mm. Incremental rotary encoder has 600 ppr resolution, high reliability, high quality, optional output mode and working voltage, manufacturer direct sale.

Absolute Encoder, 12 Bit, Single Turn, RS485/ CAN/ SSI

$155.56

SKU: ATO-RE-3912

High resolution rotary encoder with single turn, shaft encoder has RS485/ CAN/ SSI three communication interfaces for selection, with shaft diameter 6mm/ 8mm, blind hole 8mm are optional. The 12 bit absolute encoder offers high quality, high resolution and optional installation advantages.

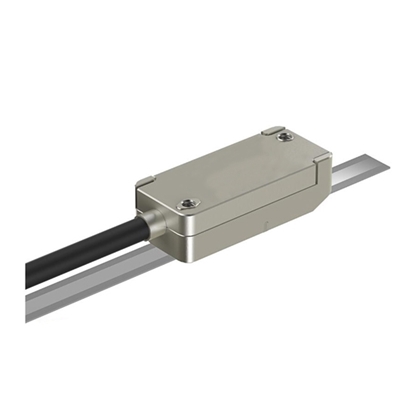

Incremental Optical Linear Encoder, Non-Contact

$542.36

SKU: ATO-LE-LGD64

Incremental optical linear encoders are available for sale at factory prices, offering optional resolutions of 0.1 µm, 0.5 µm or 1 µm to meet various accuracy requirements. The non-contact incremental linear encoder operates at a frequency of 4 MHz and has direct outlet, DB9 or DB15 output options, suitable for precise position measurement in industrial applications and precision machinery.

Absolute Encoder, 14 Bit, Single Turn, RS485/ CAN

$193.65

SKU: ATO-RE-3914

Single turn rotary encoder with single turn, 14 bit absolute encoder with natural binary code encoded output, working voltage 5V/ 24V can be chosen, the shaft encoder with shaft diameter 6mm/ 8mm, blind hole 8mm are optional. The absolute rotary encoder is used in computer input devices such as optomechanical mice and trackballs, controlled stress rheometers, and rotating radar platforms.

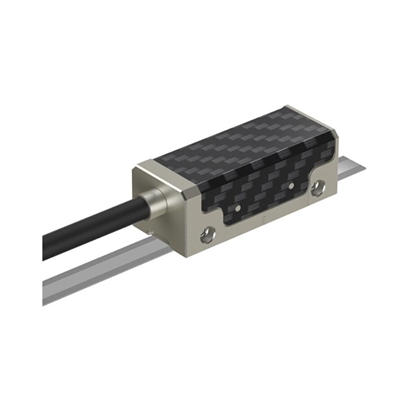

High Resolution Incremental Optical Linear Encoder, Non-Contact

$545.78

SKU: ATO-LE-LGD20

High resolution incremental optical linear encoder operates at 5V, featuring non-contact technology and selectable resolutions of 0.1 µm, 0.5 µm or 1 µm to meet diverse precision requirements. Operating at a frequency of 12.5 MHz, this linear encoder utilizes advanced non-contact optical technology to ensure measurement accuracy and stability.

Absolute Encoder, 10 Bit, Multi-turn, RS485/ CAN

$133.33

SKU: ATO-RE-39M10

High quality 10 bit rotary encoder online for sale. Multi-turn absolute encoder with RS485/ CAN two communication interfaces for selection, working voltage 5V/ 24V are optional, 10 bit absolute encoder with natural binary code encoded output. The shaft encoder is widely used computer input devices such as optomechanical mice and trackballs, controlled stress rheometers and rotating radar platforms.

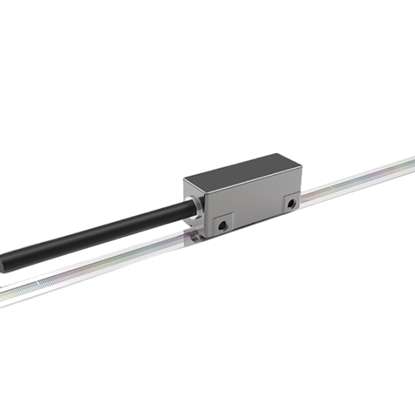

Quadrature Incremental Optical Linear Encoder, AB Phase

$513.26

SKU: ATO-LE-RST80

Quadrant incremental optical linear encoder for sale at factory price, provides AB phase or sine cosine signal output options, with a working voltage of 5V and a resolution of 1 μm. Users can choose DB9 or DB15 connectors. This non-contact optical linear encoder is suitable for industrial applications that require precise position detection and measurement.

Absolute Encoder, 12 Bit, Multi-turn, RS485/ CAN

$177.78

SKU: ATO-RE-39M12

Low cost rotary encoder with 12 bit, featuring RS485/ CAN two communication interfaces, multi-turn absolute encoder with working voltage 5V/ 24V, 24/ 50/ 99/ 1287/ 4968/ 19872 turns can be choose, the absolute rotary encoder with natural binary code encoded output. The shaft encoder offers high quality, high resolution, lower cost and long service life.

Incremental Optical Linear Encoder, ABZ, BISS

$349.26

SKU: ATO-LE-SH25

Economical price incremental optical linear encoder combines ABZ and BISS output interfaces, providing accuracy of up to 0.5 μm. The incremental linear encoder is equipped with a 9-pin D-sub connector, which can provide reliable performance and high resolution, making it a cost-effective choice.

Encoder is a device that converts angular or linear displacement into a signal, which can be used for communication, transmission and storage. Encoders have many kinds of classification form:

- According to the engraving way of coding disc: Incremental encoder and absolute encoder.

- According to the signal output type: Voltage output, open-collector output, push-pull output and line driver output.

- According to the encoder mechanical installation form: Shaft encoder, blind shaft encoder, hollow shaft encoder.

- According to the encoder working principle: Optical encoder and magnetic encoder.

Encoder

Filter by:

Clear All