Current Transformer

Solid Core Current Transformer, 50/5A, 100/5A, 150/5A, 200/5A

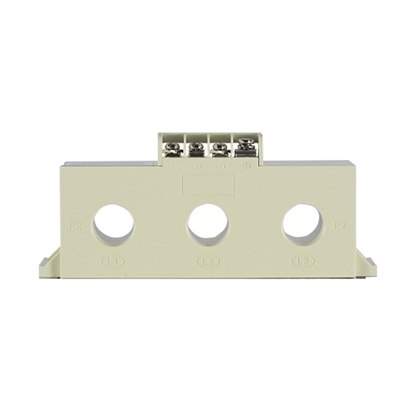

3 Phase Current Transformer, 100/5A, 200/5A, 250/5A

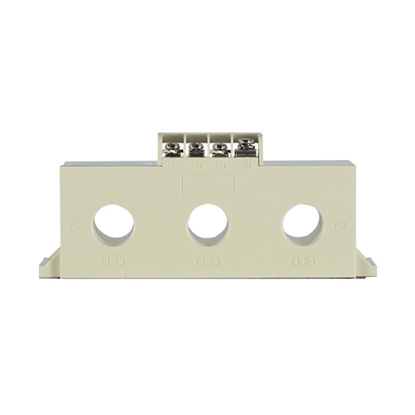

3 Phase Current Transformer, 450/5A, 800/5A, 1250/5A

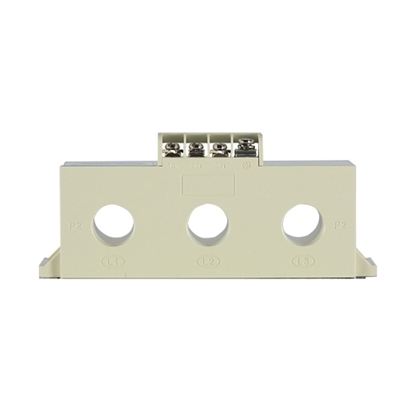

3 Phase Current Transformer, 50/5A, 75/5A, 100/5A

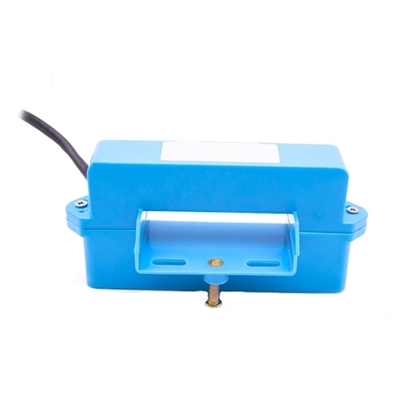

Split Core Current Transformer, 400A/5A, 800A/5A to 2000A/5A

The current transformer (CT) is an instrument that converts the primary side large current into a secondary side small current according to the principle of electromagnetic induction. The current transformer consists of a closed core and a winding. It has a small number of turns on the primary side winding, which is in the line of the current that needs to be measured.

ATO low-cost AC transformer current ratio can choose 10/5A, 30/5A, 70/5A, 100/5A, 500/5A, 2000/5A, 3000/5A, accuracy classes optional 0.5S, 0.2, 1, 0.5. The more you buy, the more discounts you have, please contact us.

How to prevent current transformer burning up?

Cause of current transformer burning up

- Secondary open circuit of the current transformer produces high voltage to burn out the current transformer.

- Long-term use of the current transformer makes the insulation aging, local breakdown or discharge occurs and overvoltage is thereof produced, thus burning out the current transformer.

- The aluminum contact surface of current transformer’s primary connection is seriously oxidized, which results in large contact resistance. The contact resistance gives out heats and burns out the current transformer.

- Long-term overload operation makes the current transformer to give out heat, it is thereof burned out.

Problems existing in the special transformer, user breaker and wiring

- Generally, both the 10kV vacuum breaker and SF6 breaker have the over-current protection and overload protection, they can trip correctly when there’s an interphase short circuit or overload, overvoltage is solved by the equipped Zinc Oxide arrester. All current transformers for metering user high voltage of our special transformer are installed between the disconnecting switch and breaker, therefore, once the current transformer gets wrong and the breaker and arrester are unable to remove fault, the upper breaker trips to eliminate the fault and expand the power failure coverage, the current transformer will be burned out at the same time due to delayed removal of faults

- When the single-phase grounding happens at the user side and the breaker doesn’t trip, we have to cut off the branches of a same common line gradually to find a ground point, as a result, the common line will be powered off and the power outage range increases.

- Insulation of the lighting arrester at the user side becomes aging, so it can’t effectively prevent the overvoltage.

Countermeasures

- Add a watchdog breaker and avoid the power failure of whole feeder line caused by faults on branches, particularly, ensure that the branch breaker can trip correctly in case of single-phase grounding at the user side.

- Connect the metering current transformer downstream the breaker, so as to guarantee that the breaker and lightning arrester operate correctly to remove faults when the transformer breaks down.

- Strengthen the flashing test for user’s high voltage metering current transformer and lightning arrester (it shall not be more than 4 years according to regulations), find out the aging degree of current transformer and lightning arrester insulation as early as possible, replace timely to avoid power failure caused by burning out of metering current transformer.

- Clean the user primary device regularly to reduce the occurrence of flashover, avoid insulation reduction.

Types of current transformers

Classification by application

- Current transformers for measurement

- Current transformer for protection

Classification by insulation medium

- Dry type current transformer

- Casting type current transformer

- Oil-immersed current transformer

- Gas insulated current transformer

Classified by installation method

- Through current transformer

- Column type current transformer

- Casing type current transformer

- Bus bar type current transformer

Classified by principle

- Electromagnetic current transformer

- Electronic current transformer

Current transformer fault analysis

Overheating phenomenon occurs. Current transformer overheating, smoke, flow of rubber and other phenomena, the cause may be a poor contact with the primary side of the wiring, the secondary side of the terminal board surface oxidation is serious, the current transformer turns between the line short circuit or one, the secondary side insulation breakdown caused.

Secondary side open circuit. At this time, the current meter suddenly no indication, current transformer sound increased significantly, in the open circuit near the smell of ozone and hear a slight discharge sound.

The hazards of the secondary side open circuit are:

- Generate very high voltage, causing a threat to the safety of equipment and operating personnel.

- Increased core loss, serious heat may burn equipment.

- Cores produce magnetic saturation, so that the current transformer error increases.

Internal discharge sound or discharge phenomenon. If the current transformer surface discharge phenomenon, may be the transformer surface is too dirty to make the insulation reduced. Internal discharge sound is the current mutual inductor internal insulation is reduced, resulting in the primary side winding to the secondary side winding and the core breakdown discharge.

Internal sound is abnormal. Causes are: current transformer core fastening screws loose, core loose, silicon steel vibration increased, not with a load change of abnormal sound; some cores due to poor assembly process of silicon steel, resulting in a certain humming sound at no load or stop load; the second side of the open circuit due to magnetic saturation and flux non-sinusoidal, so that silicon steel vibration and vibration is not uniformly issued a larger noise; current transformer serious overload, so that the core vibration sound. Make the core vibration sound increased.

Oil-filled current transformer serious oil leakage. When the current transformer in operation found in one of the above phenomena, should be transferred to the load, immediately for power outage processing.

Current transformer troubleshooting

To effectively solve the problems in the transformer, the first thing to change is the environment in which it is located, can not be placed in a humid environment, and then the transformer will be replaced, in the selection of the transformer needs to be able to make it match the load, while on the line for those connected to the wrong should also be corrected.

When troubleshooting, the power supply system needs to be cut off in advance, and the lines are tested to eliminate the faults in each line little by little. In the inspection of circuit faults need to focus on safety issues, to reduce the voltage of the primary load current to a minimum, so that the voltage in the secondary circuit is also reduced. When troubleshooting staff need to wear insulated gloves and well insulated tools, and also need to operate on insulated mats. When making line corrections, line drawings also need to be cross-referenced to the construction so that the location of each line can be found accurately. Since the secondary open circuit in the current transformer is very stealthy and not easily detected, the transformer cannot be seen to have obvious signs during the inspection, but it will always be in an open condition. Therefore, it needs to be watched and listened to very carefully when it is inspected, and all kinds of small details of the phenomenon should not be easily missed.

If the wiring crimping place appeared heat phenomenon, then its operation will appear some abnormalities, this time the correct method of treatment should be the need to first polish it, so that its contact area increased, so that it can maintain a good state in contact , and then in the use of conductive paste and springs, such as compression control, so as to melt shrinkage, for the production of manufacturers, the length of the terminal block needs to Appropriate increase, and can use screws to stabilize, so that it can make its contact surface larger and more solid, to reduce the occurrence of heat failure.