Air Motors

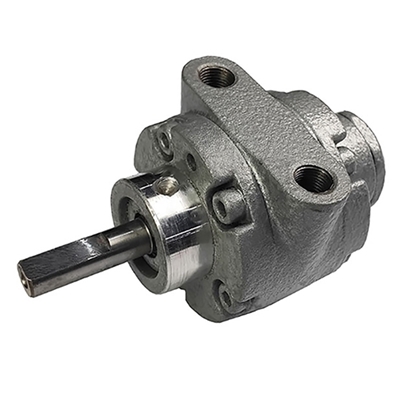

1/8 hp Piston Air Motor, 1100 rpm, 202 L/min

300W Pneumatic Vane Air Motor, 0.31Nm, 10000rpm

1/6 hp Piston Air Motor, 1000 rpm, 211 L/min

300W Vane Air Motor, 27 cfm, 6000rpm

1/4 hp Piston Air Motor, 900 rpm, 259 L/min

600W Pneumatic Vane Air Motor

1.5hp (1.2kW) Pneumatic Vane Air Motor

1/3 hp Piston Air Motor, 900 rpm, 267 L/min

1/2 hp Piston Air Motor, 750 rpm, 397 L/min

4hp (3kW) Pneumatic Vane Air Motor

3/4 hp Piston Air Motor, 700 rpm, 507 L/min

5hp (3.9kW) Pneumatic Vane Air Motor

1.5 hp Piston Air Motor, 360 rpm, 985 L/min

9.5hp (7kW) Pneumatic Vane Air Motor

Good price air motor for sale online. Air motor, also known as pneumatic motor. It is a device that converts the pressure energy of compressed air into rotating mechanical energy. Pneumatic motors are generally used as the rotating power source of complex devices or machines. Air motor provides a slew of advantages over electric motor, it is commonly used in a number of both high and low power applications.

ATO provides different types air motors for you, such as piston air motor, pneumatic vane motor. 1/8 hp, 1/6 hp, 1/4 hp, 1/3 hp, 3/4 hp, 1/2 hp, 1.5 hp, 5 hp, 9.5 hp and 700 rpm, 750 rpm, 900 rpm, 1100 rpm, 6000 rpm, 10000 rpm pneumatic motor can be chosen in our website.

ATO air motor price is affordable, high quality air motors with simple structure, small size, strong power, water resistance, fire protection, moisture and explosion proof. You can rest assured to purchase our pneumatic motor.

2 Types of Air Motor in ATO:

Piston Air Motor.

Piston air motor is a kind of pneumatic motor which transforms the linear motion of several pistons into rotary motion through crank or swash plate. Piston pneumatic motor is mainly composed of: connecting rod, crankshaft, piston, cylinder, body, valve and so on. Piston air motor is suitable for low speed and high torque. Its gas consumption is not small, and the composition of many parts.

According to pneumatic piston motor's different structure, it can be divided into two types: radial piston type and axial piston type. Piston air motors are suitable for occasions with low speed and high torque. Its gas consumption is not small, and there are many components and the price is high. Piston type air motor are mainly used in mining machinery, and which can also be used as drive motors for conveyor belts.

Vane Air Motor.

Vane air motor is a device that can convert the pressure of compressed air into rotating mechanical energy. The vane type and piston type are most widely used in pneumatic transmission.

The rotating element is a slotted rotor which is mounted on a drive shaft. Each slot of the rotor is fitted with a freely sliding rectangular vane. The vanes are extended to the housing walls using springs, cam action, or air pressure, depending on the motor design. Vane air motor. Air is pumped through the motor input which pushes on the vanes creating the rotational motion of the central shaft.

Notes For Using Air Motor:

- When the air motor is in no-load test, the gas pressure shall not be controlled between 0.1-0.5 MPa for more than 30 seconds to avoid damage to parts due to poor lubrication during high speed operation.

- Before connecting the air pipe with the pneumatic motor, the water and dirt in the pipe system should be cleaned by air blowing.

- When the pneumatic motor is working, in order to make the performance meet the design requirements, the working pressure should be guaranteed between 0.5-0.7 MPa.

- The water separator and oil mist should be installed in the system, and oil should be given at regular intervals. The amount of oil should be given according to the size of the motor.

- In use, failure or abnormal sound, should stop air motor immediately and repair.

- Pneumatic motor according to its use of regular maintenance, in order to extend its service life, maintenance period is generally 3-6 months.

4 Advantages of Air Motor:

Air motors are used for various applications in many industries such as food, chemical, agricultural, petrochemical, or even nuclear industries. They particulary fit well when speaking of very demanding or heavy duty environments as they offer four advantages.

- Safety. Air motors do not overheat or produce any sparks, so there is no risk of fire or explosion in sensitive area. pneumatic motors are not sensitive to electromagnetic phenomenon. There is no risk of “air-hammer” effect in case of jamming.

- Flexibility. The air motors' power-to-weight ratio is 5 to 6 times higher than an electric motor. So if you're dealing with an application for which the space is limited or for portable application you got here the best solution. They can operate in any position. High torque air motor does not require a sophisticated control system. It is easy to vary the torque or rotation speed with a simple installation (limiting the air supply flow or pressure). Small air motors can be used in the both rotation directions or even be reversible. pneumatic motor don't get damaged in case of rapid reversals.

- Reliability. When stalled, an air motor does not heat up or deteriorate, even at elevated cycles. The stall torque may be used to tighten at a required torque for example. High speed air motors do not generate any current peaks upon starting. pneumatic motors are continuously cooled by the supplied air expansion, preventing it from overheating, even at very high speeds.

- Productivity. There is no need for a sophisticated control and protection system (circuit breaker, contactors, variable speed drives, etc.), just a simple airflow output / pressure regulator is sufficient.

Tips For Maintain Air Motor:

- Lubricate the air motor. It is very important to lubricate the pneumatic motor with the correct oil. The compressed high torque air motor continuously generates cooling due to the expansion of the air in the pneumatic section. Even if the motor is running at very low temperatures, the oil must be liquid enough to lubricate. Therefore, the viscosity and technical properties of the oil are crucial.

- Filter air motor. Industrial air motor design is compact, if small dust or metal particles get into the pneumatic motor, they can damage the blades and possibly damage the cylinder surfaces. Installing a filter before the intake point reduces the risk of particles entering the motor.

- Store the air motor. You also have to pay attention to how to useand store the air motor. Ideally, it should be used regularly and long enough to give the oil time to lubricate the motor. If the high speed air motor is not used regularly and not long enough, make sure you have enough oil before storing-this will offset the risk of corrosion, especially in wet environments.

Air Motor Installation Steps:

- Before connecting the gas pipe of air motor, the pressurized gas should be opened first, and the dust and debris in the pipe should be removed by the pressure of the gas to ensure the cleanliness of the gas pipe.

- The inner diameter of the air pipe must be greater than or equal to the diameter of the air inlet of the pneumatic motor to ensure the air supply.

- Ensure the coaxiality between the output shaft of the air motor and the input shaft of the driver.

- Air leakage is not allowed at the interface between the air supply pipeline and the pneumatic components to ensure the air supply quality of the high torque air motor.

- The exhaust port of the high speed air motor can be installed with a matching muffler, but it cannot be completely blocked, otherwise it will affect the operation of the motor.

- For a two-way rotary vane air motor, when one of the air inlets takes in air, the other air inlet becomes a negative exhaust port, which must not be blocked.